For most consumers, fire blankets are about brands—easy to recognize, easy to trust. But for procurement professionals, OEMs, or industrial safety planners, the real priority is performance, compliance, and application fit. That means looking beyond the label and focusing on the core of every fire blanket: the fabric.

A fire blanket’s effectiveness isn’t defined by its packaging—it’s defined by its textile substrate. The base fabric determines the blanket’s thermal resistance, mechanical durability, and suppression capability under real-world conditions. It’s much like weapons engineering: ammunition often comes first, and then the delivery system is built around it. In fire protection, fabric comes first.

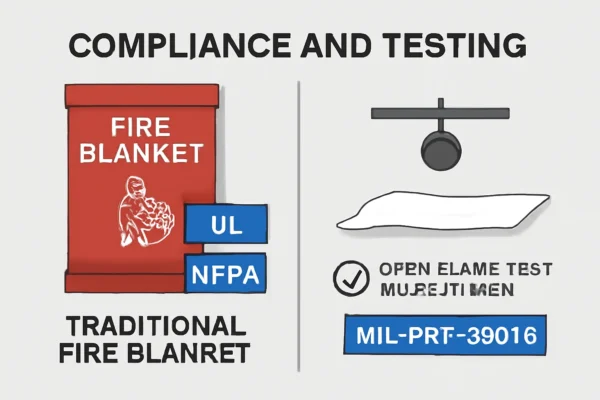

This guide classifies fire blanket base fabrics into three tiers—T0, T1, and T2—based on their temperature tolerance, durability, regulatory compliance, and suitability for various use cases. Whether you’re sourcing products certified to NFPA 701, ASTM F1989, or building out OEM inventory, understanding fabric tiers will help you make smarter, safer procurement decisions.

T0 Tier Fire Blanket Fabrics

Premium Fire Blanket Fabrics for Demanding Environments and Critical Compliance

T0-tier fire blanket fabrics are engineered for the most demanding applications—where sustained heat, molten metal exposure, or critical asset protection leaves zero margin for error. These fire blanket fabrics deliver advanced heat resistance, exceptional structural durability, and compliance with leading industry standards.

Silica Fabric

Composed of over 96% amorphous silica, this fire blanket fabric withstands continuous exposure to high temperatures up to 1000–1200°C (1832–2192°F) without structural breakdown. Its low thermal conductivity, non-combustibility, and resistance to thermal shock make it ideal for:

Welding blankets

Fire blanket wraps and curtains

Aerospace thermal shields

Battery fire safety containment covers

Silica fabric is frequently used where small fire re-ignition risk and sustained radiant heat exposure are critical.

Aluminized Coated Fiberglass

This fabric pairs a coated fiberglass base with a reflective aluminum film to provide dual-layer protection. The aluminum layer reflects up to 95% of radiant heat, while the coated fiberglass maintains tensile strength and flame resistant properties under stress. Applications include:

Smelting facilities

Gas turbines

Radiant heat shielding for firefighting gear or machinery

It’s also used in composite fire blanket fabrics requiring both insulation and radiant deflection.

Vermiculite Treated Fiberglass

A resistant fabric created by coating standard fiberglass with vermiculite minerals, this option offers enhanced abrasion resistance, long-term heat resistance, and durability under thermal cycling. It performs well up to 1000°C and is widely used in:

Heavy-duty industrial fire blanket systems

Transformer insulation covers

Marine and shipboard fire safety barriers

This high quality material strikes a cost-performance balance in the T0 category.

Brands like Z-Shield manufacture these premium materials with full certification to NFPA 701, ASTM F1989, and ISO 11612. Pricing ranges from $25 to $60 per square meter, roughly 2.5 to 4 times the cost of standard fiberglass used in T2-grade fire blankets.

The investment pays off through:

Service life up to 10 years with proper care

Stronger protection against high temperature environments

Reduced total system failure risk in regulated industries

Some OEMs offer multi-layer composite designs—like silica cores with coated fiberglass or aluminized outer skins—optimized for roles including EV battery fire containment, arc flash barriers, or small fire suppression modules. These can cost $60–$100/m² or more depending on specification.

If performance and safety are your top priorities, T0-tier fire blanket fabrics provide unmatched reliability. Materials like silica, aluminized coated fiberglass, and vermiculite-treated fiberglass deliver the heat resistance and certification compliance needed for mission-critical fire safety in extreme conditions.

T1 Tier Fire Blanket Fabrics

Cost-Effective for Industrial and Commercial Protection

T1-tier fire blanket fabrics offer a well-balanced trade-off between protection, usability, and cost. While they don’t match the high temperature endurance or mechanical strength of T0 materials, they meet the requirements of most fire safety use cases—especially in mid-risk industrial operations and consumer-grade applications. T1 fabrics are widely chosen for their durability, flexibility, and reliable performance under moderate heat resistance demands.

E-Glass Fiberglass Fabric

As the global standard in fire blanket fabric, E-glass provides heat resistance up to 550–700°C (1022–1292°F), with tensile strength around 3.4 GPa and a Limiting Oxygen Index (LOI) of 30–35. It is naturally flame resistant, lightweight, and affordable. This material is commonly used in:

Welding blankets

Light-duty fire blankets for home and workplace

Equipment insulation wraps

Its performance is sufficient for most general-purpose fire safety applications without requiring expensive surface treatments.

Silicone Coated Fiberglass

This coated fiberglass fabric features a silicone elastomer layer applied to one or both sides, improving resistance to moisture, UV degradation, oil penetration, and surface contamination. The silicone coating enhances heat resistance to about 550°C while adding excellent flexibility and surface grip. Ideal for:

Reusable welding blankets

Heat shields for machinery and ductwork

Fire curtains in commercial facilities

Silicone-coated fiberglass produces minimal smoke and toxic emissions when exposed to small fire events, making it suitable for enclosed spaces.

PU Coated Fiberglass

Polyurethane-coated fiberglass is a more economical resistant fabric designed for short-duration or light-duty fire safety. It withstands intermittent high temperature exposure up to 500–550°C and offers improved abrasion resistance and handling softness. It is frequently used in:

Portable fire blanket kits for homes or vehicles

Electrical cabinet shielding

Fire protection in light commercial or utility use

Compared to silicone coatings, PU-coated materials may emit moderate smoke under direct flame and are better suited for open-air or ventilated environments.

T1-grade fabrics are produced by both OEM manufacturers and independent mills. Many products in this tier still meet essential certifications such as NFPA 701, EN 13501, or BS 476 Part 7. However, fire blanket performance may vary depending on coating uniformity, weave density, and treatment quality. Pricing typically ranges from $8 to $20 per square meter, representing a 60–80% cost reduction compared to T0 materials.

Recommended use cases:

Bulk procurement for fire safety training kits

Disposable or portable fire blankets

Machine shops, automotive garages, logistics facilities

Commercial kitchens requiring grease or small fire shielding

T2 Tier Fire Blanket Fabrics

Disposable and Budget-Grade Fabrics

T2-tier fire blanket fabrics are designed for short-term, non-critical scenarios where cost outweighs durability or certification. These materials offer basic flame resistant characteristics and minimal heat resistance, but lack the reliability, consistency, and long-term structural integrity needed for industrial fire safety.

They are commonly used in temporary setups, consumer-grade kits, or budget-driven markets where fire blanket compliance is not a requirement.

Low-Grade Fiberglass Fabric

This fire blanket fabric is made from loosely woven, low-density glass fibers (200–350g/m²) with no surface treatment. It provides limited heat resistance—typically around 450–500°C (842–932°F)—and tends to break down quickly under mechanical stress or repeated exposure to high temperature.

Applications include:

Disposable or single-use fire blankets

Emergency covers in low-risk zones

Cost-focused consumer kits or giveaways

While technically a resistant fabric, it has poor durability and may shed fibers or tear easily, making it unsuitable for environments involving sustained heat or small fire hazards.

PVC or Acrylic Coated Fiberglass

These coated fiberglass fabrics use lightweight plastic-based coatings to improve handling and appearance. However, they deteriorate quickly in high temperature conditions and may emit smoke or fumes. Their flame resistant performance is inconsistent and typically uncertified.

Typical uses:

Promotional-grade fire blankets

Budget packaging or storage covers

Entry-level safety kits not intended for welding blankets or critical heat exposure

These fabrics may pass basic flame tests but are unreliable near active ignition sources or in environments prone to small fires.

T2-grade fabrics are often marketed through OEM vendors, wholesale sites, or private-label suppliers. Many lack essential certifications or fire safety documentation such as MSDS, despite using vague terms like “fireproof” or “thermal shield.”

Prices range from $2 to $6 per square meter, making them attractive for high-volume, one-time procurement. However, they are not substitutes for certified fire blankets in industrial or compliance-sensitive settings.

T2 fire blanket fabrics are best suited for temporary fire safety needs where price is the main factor. Materials like low-grade fiberglass and plastic-coated fiberglass may provide limited protection against small fires, but should not be relied upon for long-term use, regulated environments, or near critical heat sources. Their value lies in disposability, not in delivering high quality fire protection.

Fabrics to Avoid in Fire Blanket Applications

Asbestos-Based Fabrics

Asbestos was once widely used for its exceptional heat resistance, but it is now banned or heavily restricted across the U.S. due to its fatal health effects. Inhalation of airborne fibers can lead to mesothelioma, lung cancer, and chronic respiratory illness.

Despite strict fire safety regulations enforced by EPA and OSHA, asbestos-containing fire blankets occasionally appear in secondary markets or outdated inventories. These should be removed and professionally disposed of without delay.

Uncoated Ceramic Fiber Cloth

Although ceramic fabrics can tolerate high temperature exposure (up to 1200°C), uncoated or poorly stabilized types pose serious health and usability concerns. They shed airborne irritants, lack pliability, and often crack under mechanical stress.

In high-performance settings like welding blankets, ceramic materials may be used only when encapsulated within coated fiberglass layers. They are not appropriate for general-purpose fire blanket manufacturing, especially when human contact is possible.

Recycled or Unknown-Origin Fabrics

Unverified textiles—such as second-hand insulation pads or repurposed resistant fabric—are unpredictable. They usually lack:

Certified flame resistant treatment

Documentation confirming heat resistance

Compliance with recognized fire safety standards like NFPA 701 or EN 13501

These materials may be mislabeled as fire blankets and sold through low-end OEMs or online marketplaces. Always demand full compliance documentation before purchase.

Selecting the right fire blanket fabric isn’t just about choosing a material—it’s about aligning your fire protection strategy with performance, compliance, and risk level.

For critical, high-risk environments, T0 fabrics like high-grade coated fiberglass and vermiculite-treated glass offer unmatched heat resistance and reliability.

For most general-use applications, T1 fabrics strike a cost-effective balance with certified, durable flame resistant performance.

T2 materials, while budget-friendly, should only be used in temporary or non-regulated scenarios where minimal protection is acceptable.

And most importantly—avoid banned or undocumented fabrics like asbestos or recycled textile blends that compromise both fire safety and human health.

If you’re a fire safety buyer, OEM integrator, or sourcing manager, working with a trusted supplier can simplify the decision-making process.

Safeprotex, as a certified manufacturer of professional-grade fire blankets , offers solutions tailored to commercial, industrial, and government procurement needs. From material selection to regulatory documentation, their team helps ensure your fire protection strategy is compliant and future-proof.

Contact a Safeprotex specialist today to find the right fire blanket fabric tier for your specific application—with no guesswork, and no compromise.