For fire safety agencies and companies in the United States as well as the Middle East, the National Fire Protection Association (NFPA) remains the most influential authority in setting codes and standards. Whether addressing traditional building fires or emerging hazards, NFPA guidelines have become the default—or even mandatory—framework for compliance. With the rapid rise of electric vehicles (EVs) and the new fire risks associated with lithium-ion batteries, NFPA has been quick to issue guidance tailored to these challenges. Key references include NFPA 855 (Standard for Energy Storage Systems), the NFPA Alternative Fuel Vehicles Emergency Field Guide, and updates across related standards such as NFPA 70® (National Electrical Code) and NFPA 70B on electrical equipment maintenance. Together, these documents provide the baseline for understanding, preventing, and responding to EV fire incidents.

NFPA and the EV Fire Challenge

For fire safety agencies and companies in the United States as well as the Middle East, the National Fire Protection Association (NFPA) remains the most influential authority in setting codes and standards. Whether addressing traditional building fires or emerging hazards, NFPA guidelines have become the default—or even mandatory—framework for compliance. With the rapid rise of electric vehicles (EVs) and the new fire risks associated with lithium-ion batteries, NFPA has been quick to issue guidance tailored to these challenges. Key references include NFPA 855 (Standard for Energy Storage Systems), the NFPA Alternative Fuel Vehicles Emergency Field Guide, and updates across related standards such as NFPA 70® (National Electrical Code) and NFPA 70B on electrical equipment maintenance. Together, these documents provide the baseline for understanding, preventing, and responding to EV fire incidents.

NFPA Standards for EV Fire Safety

Two NFPA pillars shape EV fire safety in facilities and fleets: NFPA 855 for energy-storage risk control and NFPA 70® / NFPA 70B for electrical safety and maintenance.

NFPA 855 — limiting propagation and hazardous effects.

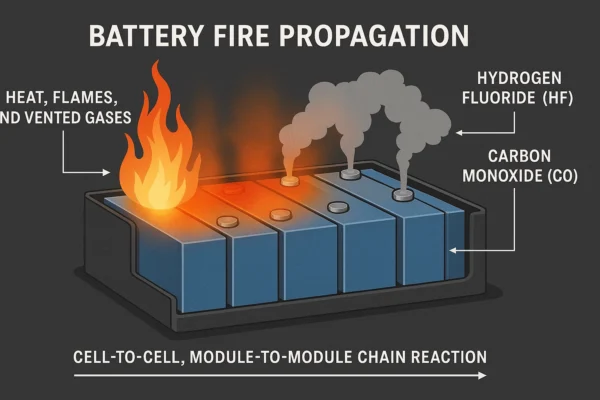

NFPA 855 requires designs and validations that address thermal runaway propagation and hazardous byproducts. In practice, systems must either prevent cell-to-cell spread or demonstrate acceptable outcomes via UL 9540A testing across the cell → module → unit → installation sequence, which characterizes flame spread, heat release, deflagration potential, and gas output (e.g., HF/CO).

Many jurisdictions and guidance documents derived from NFPA 855 also apply energy caps by fire area (commonly ≈600 kWh without enhanced mitigation), require separation of ESS groupings (e.g., 50 kWh blocks spaced ~3 ft), and trigger additional protection or UL 9540A evidence when those criteria can’t be met. These quantitative limits give authorities having jurisdiction (AHJs) and fire marshals measurable criteria during plan review.

NFPA 70® (NEC) — EVSE installation safety.

Article 625 of the NEC governs electric-vehicle supply equipment (EVSE)—from dedicated branch circuits and overcurrent protection to ground-fault protection and emerging allowances for multiple EVSE on a branch when an energy management system is used. Correct branch sizing, wiring methods, and protection are foundational to prevent electrical faults that could precipitate pack heating during charge.

NFPA 70B — making maintenance enforceable.

Since the 2023 edition, NFPA 70B moved from guidance to a mandatory maintenance standard, requiring condition-based programs (equipment condition assessment), defined testing (e.g., IR thermography, insulation resistance), and documented inspection intervals—in EV contexts often annual unless usage/environment dictates more frequent work. This materially lowers ignition risk at chargers and distribution equipment in depots and public sites.

What this means for businesses and fire departments.

For operators/AHJs: NFPA 855 + UL 9540A provide propagation-control evidence and caps/separations that reduce worst-case scenarios; NEC/70B keep EVSE and feeders within safe electrical margins during heavy use.

For firefighters: facilities that comply with 855/9540A are more likely to slow spread, provide venting/clearances that reduce explosive gas accumulation, and offer better pre-incident data for size-up. NEC/70B compliance reduces the chance that a charging fault escalates into a pack-level event, aligning with NFPA field guidance on isolation, cooling, and long-duration monitoring.

NFPA Field Guide and Tactical Response

Two NFPA pillars shape EV fire safety in facilities and fleets: NFPA 855 for energy-storage risk control and NFPA 70® / NFPA 70B for electrical safety and maintenance.

NFPA 855 — limiting propagation and hazardous effects.

NFPA 855 requires designs and validations that address thermal runaway propagation and hazardous byproducts. In practice, systems must either prevent cell-to-cell spread or demonstrate acceptable outcomes via UL 9540A testing across the cell → module → unit → installation sequence, which characterizes flame spread, heat release, deflagration potential, and gas output (e.g., HF/CO).

Many jurisdictions and guidance documents derived from NFPA 855 also apply energy caps by fire area (commonly ≈600 kWh without enhanced mitigation), require separation of ESS groupings (e.g., 50 kWh blocks spaced ~3 ft), and trigger additional protection or UL 9540A evidence when those criteria can’t be met. These quantitative limits give authorities having jurisdiction (AHJs) and fire marshals measurable criteria during plan review.

NFPA 70® (NEC) — EVSE installation safety.

Article 625 of the NEC governs electric-vehicle supply equipment (EVSE)—from dedicated branch circuits and overcurrent protection to ground-fault protection and emerging allowances for multiple EVSE on a branch when an energy management system is used. Correct branch sizing, wiring methods, and protection are foundational to prevent electrical faults that could precipitate pack heating during charge.

NFPA 70B — making maintenance enforceable.

Since the 2023 edition, NFPA 70B moved from guidance to a mandatory maintenance standard, requiring condition-based programs (equipment condition assessment), defined testing (e.g., IR thermography, insulation resistance), and documented inspection intervals—in EV contexts often annual unless usage/environment dictates more frequent work. This materially lowers ignition risk at chargers and distribution equipment in depots and public sites.

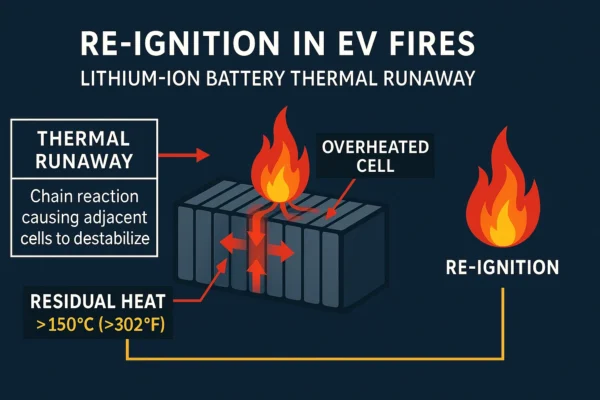

NFPA also highlights the hazard of “stranded energy”—residual charge that can trigger delayed re-ignition hours after apparent knockdown. Lithium-ion batteries have been documented to re-ignite multiple times within a 24-hour window. Because of this, crews should anticipate flare-ups, continue intermittent or sustained cooling until TIC readings show a stable downward trend, and maintain an isolation zone ≥50 ft from exposures. Post-incident, vehicles should be monitored or stored in a ventilated, quarantined area for ≥24 hours, with periodic thermal scans and gas monitoring. If towing is required, responders must hand off clear instructions to storage providers about re-ignition risks and the need for extended monitoring.

What this means for businesses and fire departments.

For operators/AHJs: NFPA 855 + UL 9540A provide propagation-control evidence and caps/separations that reduce worst-case scenarios; NEC/70B keep EVSE and feeders within safe electrical margins during heavy use.

For firefighters: facilities that comply with 855/9540A are more likely to slow spread, provide venting/clearances that reduce explosive gas accumulation, and offer better pre-incident data for size-up. NEC/70B compliance reduces the chance that a charging fault escalates into a pack-level event, aligning with NFPA field guidance on isolation, cooling, and long-duration monitoring.

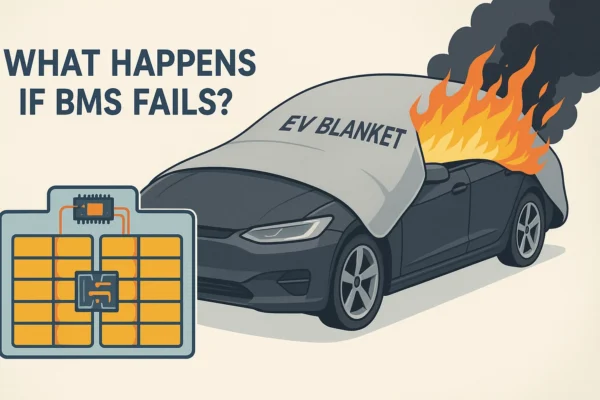

Safeprotex supports NFPA’s EV fire guidance with advanced EV Fire Blankets. Designed to contain flames, limit smoke, and protect exposures, our solutions give firefighters and businesses practical tools to manage EV fire risks with safety, compliance, and confidence. Connect with our team today.