Since 2020, electric vehicles (EVs) have grown rapidly, reshaping global transportation. Yet this shift also brings new safety concerns—especially thermal runaway, battery fires, and high-voltage faults. Because most of these hazards stem from the battery pack, regulators, manufacturers, and fire departments are paying closer attention to how risks are managed.

At the center of this effort is the Battery Management System (BMS)—a critical safeguard that continuously monitors and controls the battery cells to keep them within their safe operating area. By regulating charges and discharges, tracking State of Charge (SoC) and State of Health (SoH), and intervening when the temperature of the battery moves outside its designed temperature range, the BMS supports battery performance, extends battery life, and helps prevent incidents. For first responders, this means safer interaction with high-voltage lithium-ion batteries, while for consumers, it ensures greater reliability of their rechargeable battery systems.

Battery Management System (BMS)

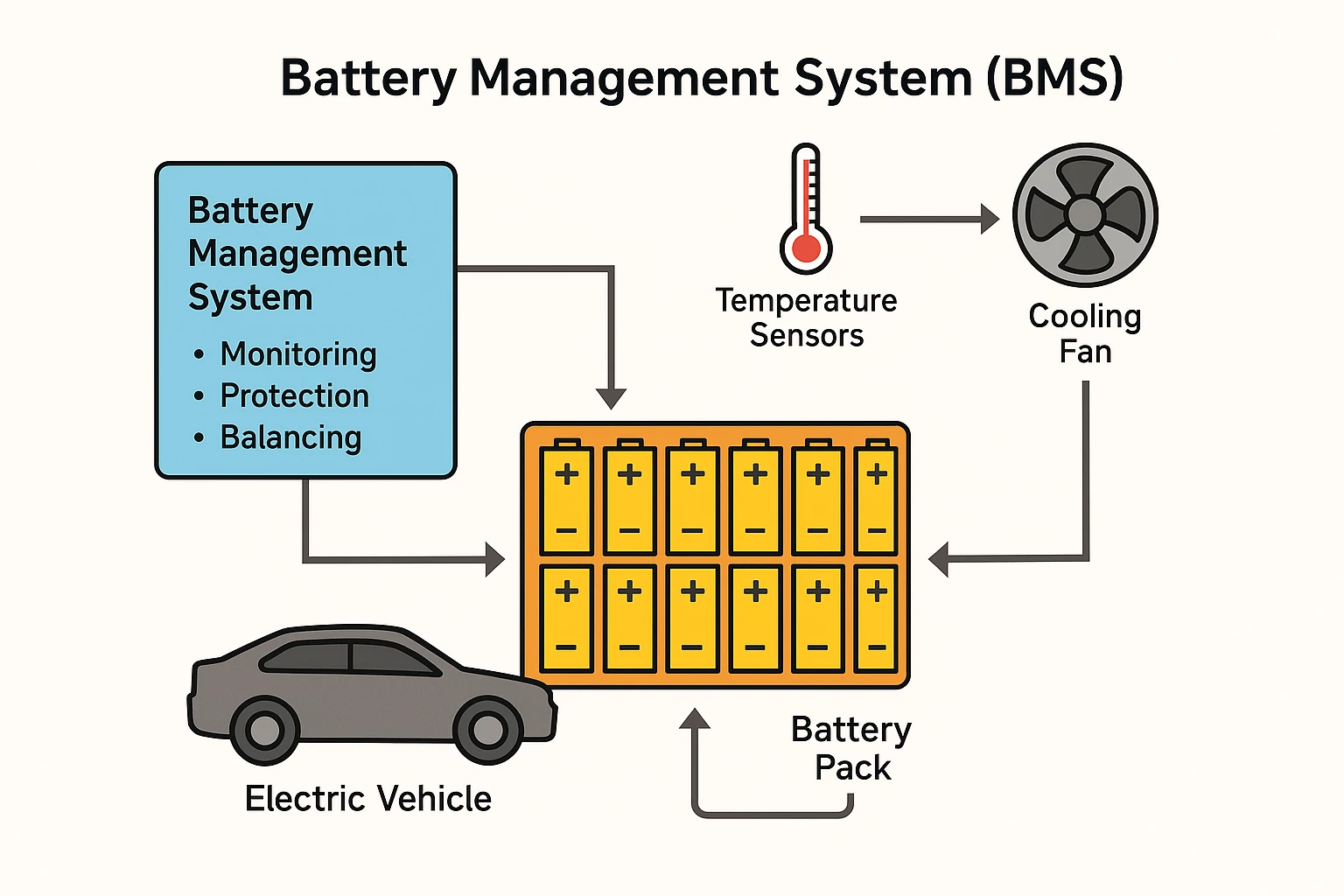

A Battery Management System (BMS) is the electronic safety and control layer for an EV battery pack. It ensures the battery cells operate within their safe operating area to deliver reliable battery performance, protect against thermal runaway, and extend battery life. In practice, the BMS continuously monitors and controls voltage, current, and the temperature of the battery, coordinating how the pack charges and discharges under all operating conditions.

State estimation: Tracks State of Charge (SoC) and State of Health (SoH) using sensor data, models, and coulomb counting.

Protection & supervision: Detects over/undervoltage, overcurrent, short circuits, isolation faults, and out-of-range temperature events; enforces limits or shutdowns to keep operation within the defined temperature range and voltage/current windows (e.g., many lithium ion battery chemistries are managed around ~2.5–4.2 V per cell as a typical window).

Cell balancing: Performs cell balancing (passive or active) to equalize states among cells and slow degradation.

High-voltage control: Manages pre-charge, contactors, and in some designs pyrotechnic disconnects after severe faults or collisions.

Thermal management coordination: Interfaces with vehicle thermal management to command cooling systems or heating to stabilize the temperature of the battery.

Diagnostics & communications: Logs fault codes, timestamps, and trends; communicates with the charger, vehicle control unit, and telematics for service and safety notifications.

MS design and validation are anchored in ISO 26262 (functional safety), with appropriate ASIL targets, diagnostics, redundancy, and safe-state strategies. At the pack and vehicle level, programs typically align with U.S. safety frameworks such as UL 2580, SAE J2929, and FMVSS 305.

BMS Architectures

Centralized architecture: A single controller manages all battery cells in the battery pack—simple and cost-effective for smaller packs.

Distributed architecture: Module-level controllers measure cells and feed a master unit—favored for larger packs due to wiring practicality and scalability.

Modular architecture: A hybrid that combines distributed sensing with centralized decision logic; common in high-capacity lithium ion battery systems (e.g., buses and commercial electric vehicles (EVs)).

Wireless BMS (wBMS, emerging): Reduces wiring harness mass/complexity while maintaining cell-level telemetry via secure wireless links.

How a BMS Works

Sensors measure per-cell voltage, pack current, and multiple temperature points. Estimation algorithms compute SoC and SoH, while safety logic compares real-time data to calibrated thresholds. If conditions drift outside the safe operating area or the temperature range becomes unsafe, the BMS derates power, limits charging, commands cooling systems, or opens contactors to prevent escalation. Severe anomalies can trigger immediate HV isolation and service alerts via telematics.

In electric vehicles (EVs), the Battery Management System (BMS) is central to safety and reliability. By supervising the battery pack, it prevents thermal runaway, regulates charges and discharges, balances battery cells, and works with thermal management and cooling systems to keep the temperature of the battery within its safe range. These functions directly shape battery performance and extend battery life.

Beyond passenger cars, BMS technology is critical in buses and heavy-duty trucks that use large lithium ion battery systems, where modular designs ensure fault detection and scalability. For first responders, BMS data on faults and pack status supports safer immobilization and post-incident handling of high-voltage rechargeable battery systems.

Ultimately, the BMS is the gatekeeper that transforms raw battery energy into safe and dependable propulsion—without it, EV safety and trust would not be possible.

Why Is a BMS Essential in EVs?

The Battery Management System (BMS) is not an optional feature—it is fundamental to the safety, reliability, and performance of electric vehicles (EVs). Without it, a lithium ion battery pack is vulnerable to uncontrolled charges and discharges, excessive heat buildup, and imbalance among battery cells, all of which increase the likelihood of failures or even fire.

Safety First:A BMS ensures the pack operates within its safe operating area by supervising voltage, current, and the temperature of the battery. It prevents the conditions that can trigger thermal runaway, such as overvoltage, deep discharge, or overheating. By coordinating with the vehicle’s thermal management system and activating cooling systems when necessary, it reduces fire risk and protects drivers, passengers, and first responders. This function is critical not only for vehicle occupants but also for fire departments that must safely manage post-crash or post-fire rechargeable battery incidents.

Performance and Longevity:The BMS is also essential for maintaining consistent driving range and extending battery life. By tracking State of Charge (SoC) and State of Health (SoH), it helps ensure predictable driving distances and slows capacity fade over time. Advanced cell balancing prevents weaker cells from limiting overall capacity, helping the vehicle deliver stable battery performance throughout its service life. For example, without cell balancing, one degraded cell could prematurely reduce a pack’s usable range.

System Integration:Modern EVs depend on the BMS as the bridge between the battery pack and the Vehicle Control Unit (VCU), charging system, and diagnostic platforms. This integration enables safe fast charging, regenerative braking, and predictive maintenance. High C-rate charges and discharges, for instance, would cause overheating or lithium plating without accurate BMS supervision. For regulators, the BMS is also a compliance requirement under standards such as UL 2580, SAE J2929, and FMVSS 305, which define safety expectations for EV batteries in the U.S.

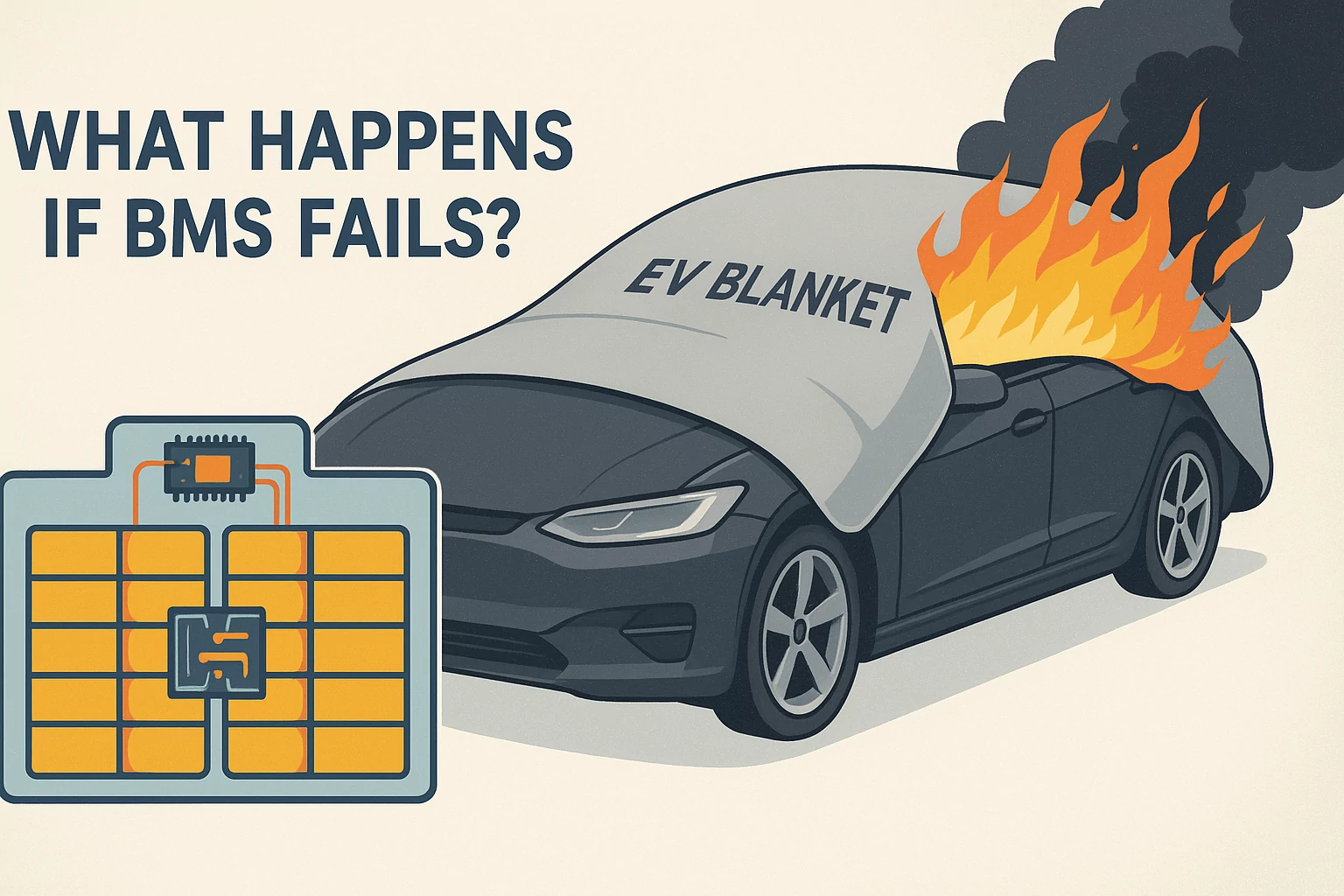

What Happens if BMS Fails?

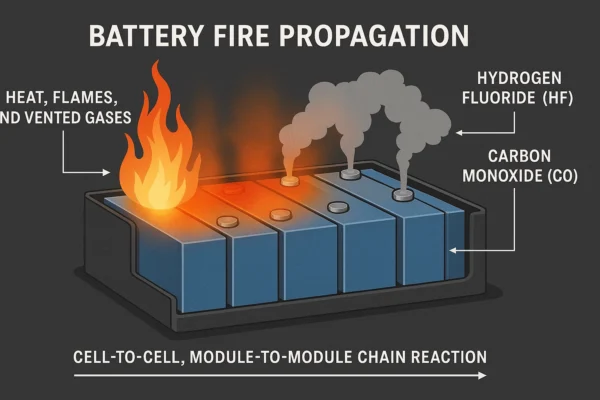

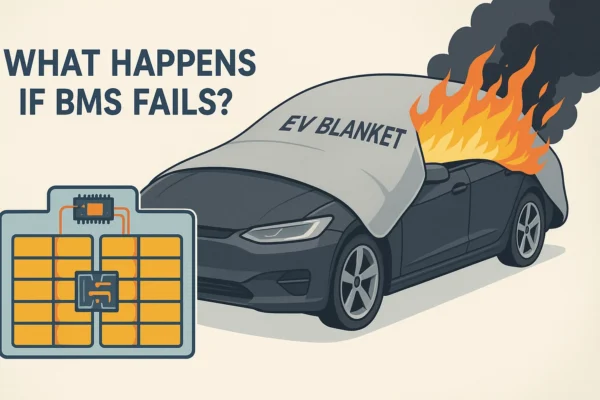

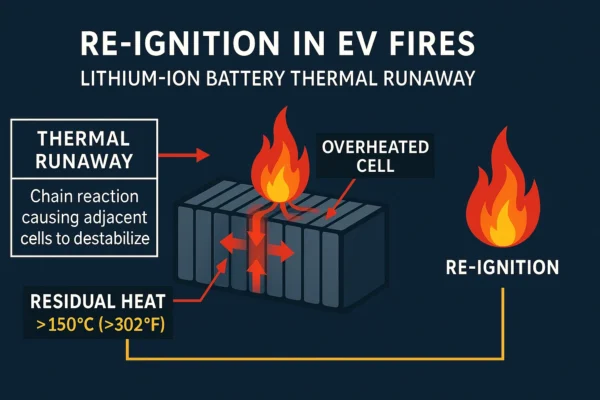

When a Battery Management System (BMS) fails, the functional safety barrier defined under standards such as ISO 26262 is effectively lost. Normally, the BMS continuously monitors and controls the battery pack to keep voltage, current, and the temperature of the battery within the safe operating area. Without these protections, conditions like uncontrolled charges and discharges, cell balancing failures, or overheating can quickly drive the battery cells outside their limits. In this state, the likelihood of thermal runaway increases sharply, and once initiated, the reaction can propagate through the pack, releasing extreme heat—often exceeding 1,000 °C—along with sparks, flames, and hazardous vapors such as hydrogen fluoride and carbon monoxide. Unlike conventional vehicle fires, where water or foam can directly extinguish flames, a lithium ion battery fire is driven by internal chemical reactions, making suppression far more complex. Water may still provide external cooling, but it cannot stop the runaway process inside the cells.

For fire departments, these realities explain both the importance of a functioning BMS and the need for contingency measures when failures occur. One of the most effective current strategies is the deployment of specialized EV blankets, which are already in use across many U.S. and European fire services. By fully covering the vehicle, these blankets contain flames, reduce radiant heat, and help block the release of toxic smoke, creating a safer perimeter around the incident. More importantly, they provide critical time for the rechargeable battery to cool and for responders to stabilize the situation without exposing themselves to ongoing emissions.

Ultimately, while BMS failures are rare thanks to rigorous automotive design and testing, they highlight the dependence of electric vehicles (EVs) on this system for safety. They also underscore why both advanced engineering controls and practical firefighting solutions—such as EV blankets—are indispensable in preventing escalation and protecting people, property, and the environment.

Lifespan, Maintenance, and Inspection

The Battery Management System (BMS) is generally engineered to last for the full service life of an electric vehicle (EV), aligning with the durability of the lithium ion battery pack it protects. In most cases, the BMS requires no direct mechanical maintenance, since its core functions are electronic and software-driven. However, it is important to recognize that under harsh operating conditions—such as high vibration in heavy-duty vehicles or prolonged exposure to high ambient temperatures—the electronic control modules can degrade faster than the battery cells themselves.

Routine inspection is therefore recommended. For consumer vehicles, this typically occurs during annual service visits, while for fleet and emergency-use electric vehicles (EVs), more frequent checks are advisable. Inspections involve verifying the accuracy of State of Charge (SoC) and State of Health (SoH) reporting, ensuring that cell balancing functions are active, and confirming that the system continues to monitor and control the temperature of the battery within its designated temperature range. Technicians often rely on diagnostic tools or the vehicle’s OBD-II interface to read fault codes and assess battery performance trends.

In addition, BMS software updates may be issued through OEM service bulletins or recalls, particularly to improve algorithms for thermal management, optimize cooling systems, or refine fault detection. Responding promptly to dashboard fault codes or alerts is critical to keeping the BMS in proper working order. For consumers, this usually means following manufacturer service schedules, while fleet operators may schedule log analysis as part of predictive maintenance. For fire departments and safety agencies, reviewing BMS diagnostic logs after an incident can reveal how the system behaved leading up to failure, offering valuable insights to improve post-crash response.

In short, while the BMS is designed for long-term reliability, structured inspection and timely software updates ensure it continues to safeguard battery life, enhance safety, and support the overall reliability of modern rechargeable battery systems.

the Battery Management System (BMS) is the critical safeguard that ensures electric vehicles (EVs) operate safely, extending battery life and reducing the risk of thermal runaway. Understanding its role—from monitoring and protection to failure response—is essential for consumers, regulators, and fire departments alike.

In Safeprotex, a specialized manufacturer of EV fire blankets. We provide a full range of EV Blankets designed to contain diverse types of EV fires. Connect with our expert team today to access the most professional and reliable EV fire solutions.