In August 2024, a fire in an underground parking garage in Incheon, South Korea began in a parked Mercedes-Benz EV’s lithium-ion battery and took over eight hours to control—damaging about 140 vehicles and sending 23 people to the hospital. This event illustrates how ignition in a single cell can escalate into battery fire propagation—cell-to-cell and even vehicle-to-vehicle spread. For U.S. fire departments and safety professionals, understanding how propagation starts, accelerates, and is contained directly informs tactics, exposure protection, and post-incident planning.

What Is Battery Fire Propagation?

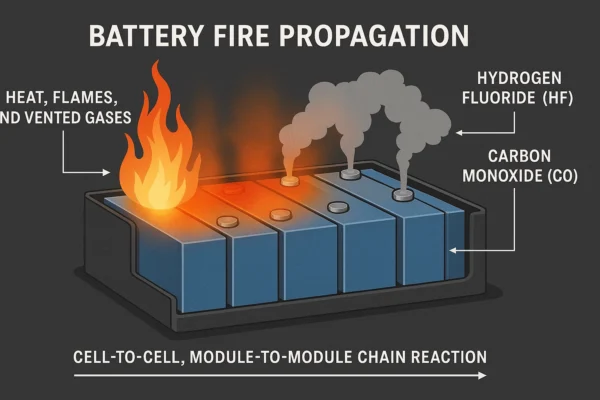

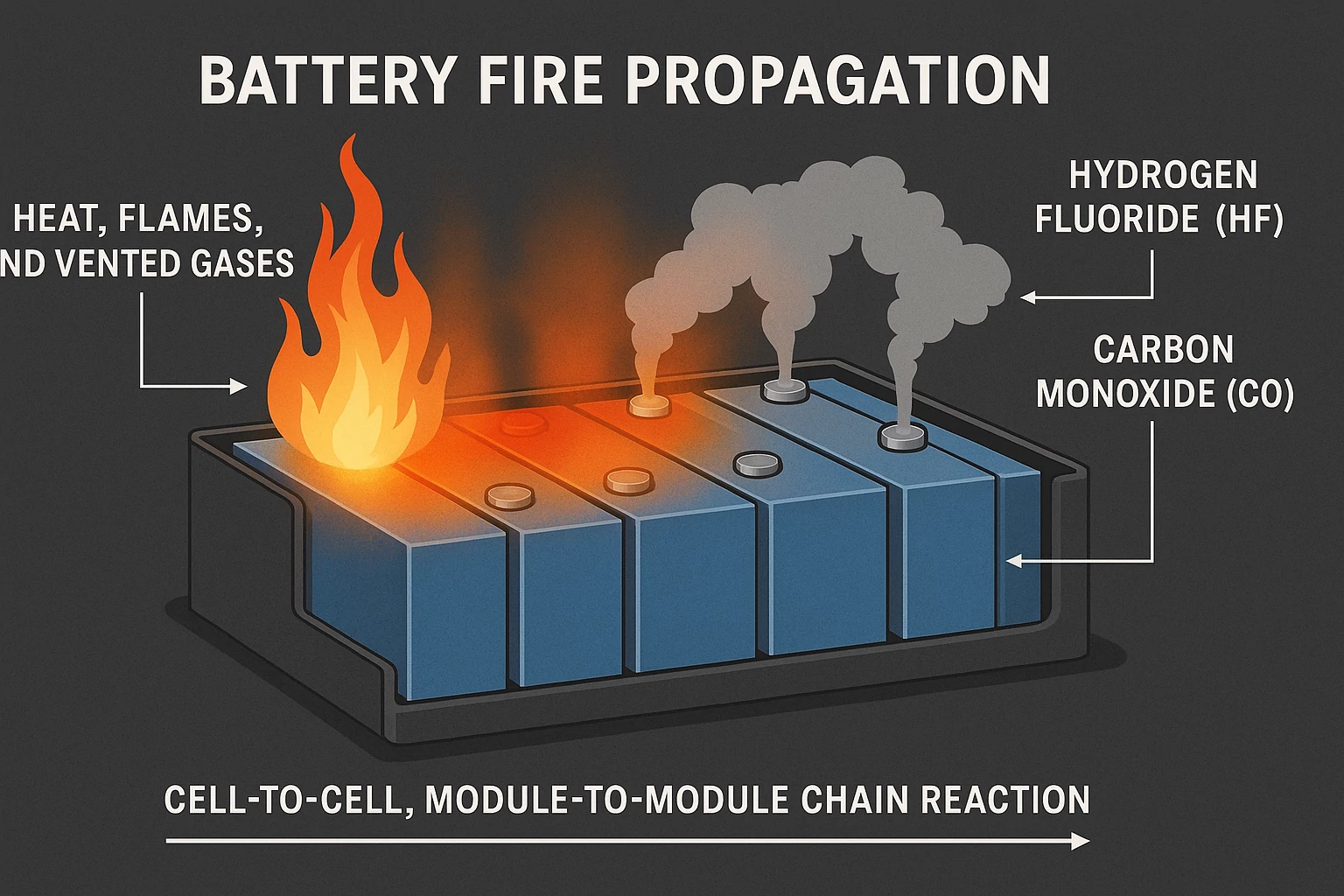

Battery fire propagation is the mechanism by which heat, flames, and vented gases from one failing battery cell drive adjacent cells in a lithium-ion battery pack beyond their safe operating area, forcing them into thermal runaway. The result is a chain reaction—cell-to-cell, often module-to-module—that can escalate a localized fault into a pack-level or even vehicle-to-vehicle event. Propagation is driven by extreme thermal flux and combustible vapors: during runaway, cell surfaces can exceed 500–1000 °C, while hazardous gases such as hydrogen fluoride (HF) and carbon monoxide (CO) are released as the temperature of the battery surpasses its designed temperature range.

Engineers characterize and mitigate propagation using U.S.-referenced test methods such as UL 9540A (fire propagation and gas/heat release characterization for lithium-ion systems) and SAE J2464 (EV battery safety testing), which inform choices like thermal barriers, vent paths, fusing, and shutdown strategies. For first responders, understanding propagation—its triggers, timelines, heat release, and gas hazards—guides size-up, evacuation, exposure protection, and containment tactics during electric-vehicle (EV) incidents involving large rechargeable battery systems.

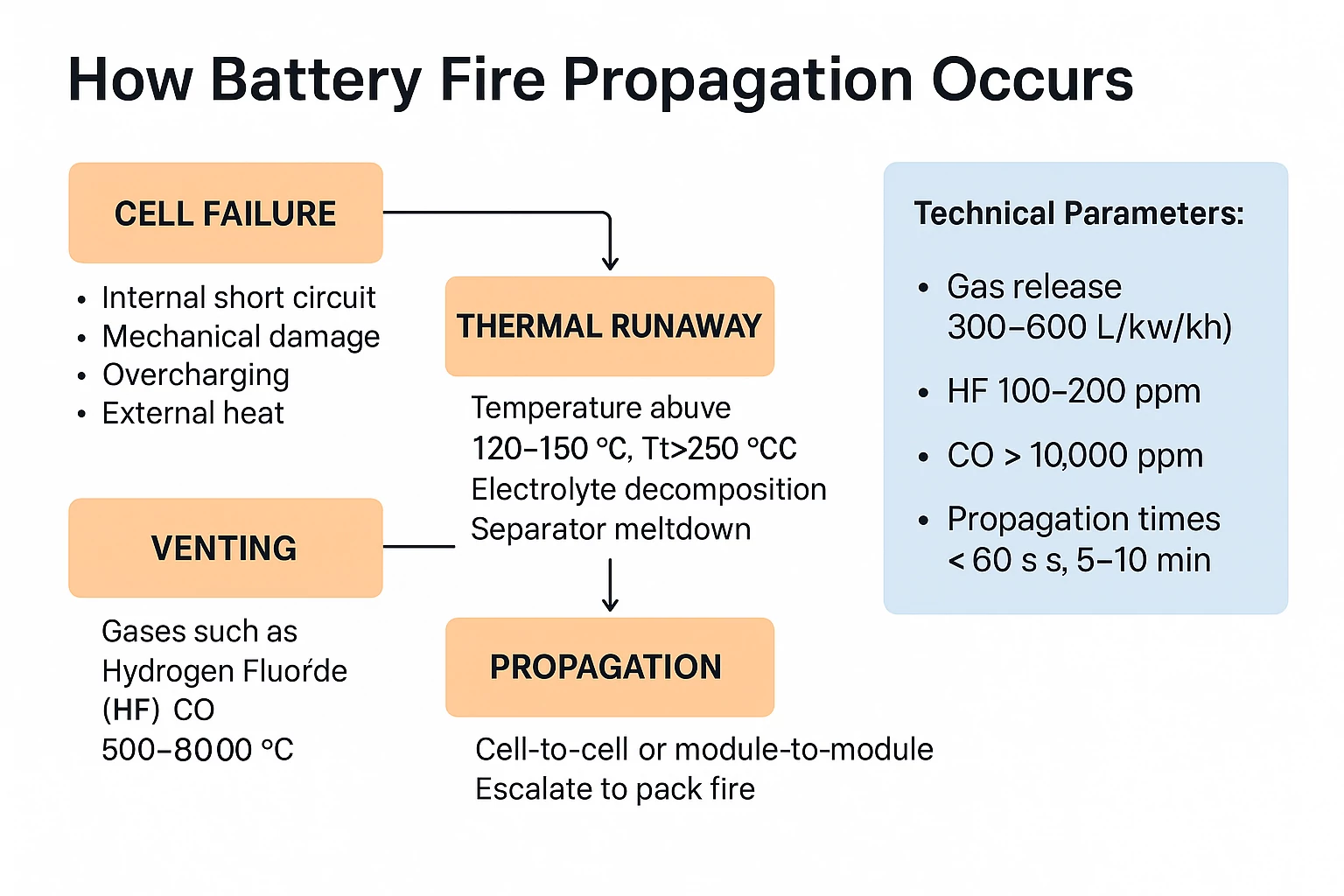

How Battery Fire Propagation Occurs

The process of battery fire propagation begins when a single battery cell fails, often due to internal short circuits, mechanical damage, overcharging, or exposure to external heat. Once the cell exceeds its safe operating area, the temperature of the battery rises rapidly—typically above 120–150 °C, which initiates electrolyte decomposition and gas generation. At around 200–250 °C, separator meltdown occurs, creating internal shorts and triggering thermal runaway.

During runaway, cell surface temperatures can exceed 500–800 °C, with localized hot spots surpassing 1000 °C in some large-format cells. Gas release rates measured in propagation tests often reach 300–600 liters per kilowatt-hour (L/kWh) of battery capacity, containing toxic species such as hydrogen fluoride (HF) at concentrations above 100–200 ppm and carbon monoxide (CO) exceeding 10,000 ppm.

As heat and high-pressure gases are expelled, neighboring battery cells absorb this energy. If their temperature range rises above 180–200 °C, they too enter runaway. Propagation can occur in under 60 seconds between adjacent cells, and escalate to a full module-level fire within 5–10 minutes, depending on pack design, thermal insulation, and venting. This chain reaction continues cell-to-cell and module-to-module, quickly compromising the entire battery pack.

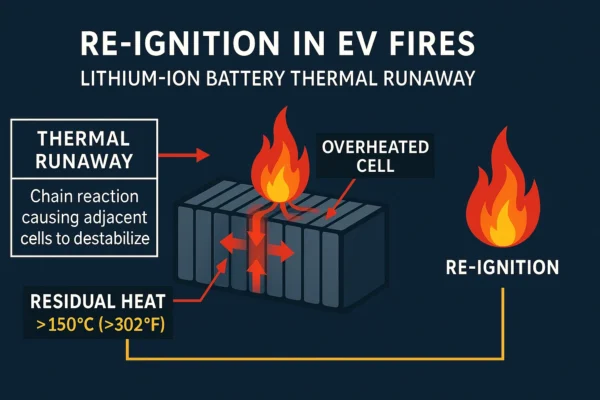

Research under standards like UL 9540A and SAE J2464 confirms that once propagation begins, conventional suppression agents (e.g., water or foam) cannot stop internal reactions in lithium ion batteries. Water applied at 100–500 gallons per minute (GPM) can reduce external temperatures but does not halt runaway. For electric vehicle (EV) incidents, this means firefighters face risks of delayed re-ignition, sometimes 8–24 hours after initial suppression. Recognizing these parameters helps first responders plan effective cooling, exposure protection, and containment strategies—such as deploying EV blankets or advanced thermal management systems.

Threats and Containment

Once battery fire propagation begins, the threat profile escalates quickly: cell and module surfaces can reach 800–1000 °C, jet flames and pressure pulses drive cell-to-cell spread, and vented gases can include hydrogen fluoride (HF) (often ≥100–200 ppm) and carbon monoxide (CO) (frequently >10,000 ppm). Re-ignition can occur hours later (≈8–24 h) after apparent knockdown, creating risks for overhaul, towing, and storage. In parking structures or multi-vehicle incidents, radiant heat can ignite adjacent vehicles; responders also face high-voltage hazards and corrosive off-gassing. U.S. practice and research (e.g., NFPA AFV Emergency Field Guide, NFPA 855 for ESS, UL 9540A/ SAE J2464 testing) prioritize rapid size-up, exposure protection, and gas/thermal monitoring.

Layered containment combines prevention, rapid isolation, and cooling:

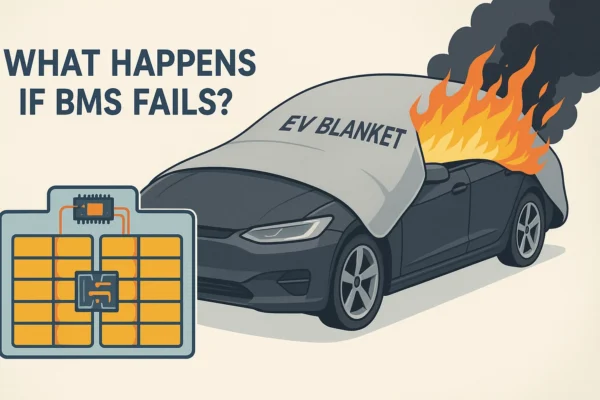

Prevention via BMS (first layer). The Battery Management System (BMS) continuously monitors and controls voltage, current, and the temperature of the battery to keep cells within the safe operating area; it detects faults, performs cell balancing, derates power, opens contactors, and coordinates thermal management / cooling systems. Robust BMS design aligned with ISO 26262, UL 2580, and SAE J2929 reduces the likelihood that propagation starts at all.

EV fire blankets (front-line scene control). When propagation or open flame is present, EV blankets provide fast, tool-free containment: they cap flames, reduce radiant heat to nearby exposures, and help confine toxic smoke. Typical operational benefit is ~10–30 minutes of improved control/visibility for repositioning apparatus, protecting adjacent vehicles/structures, and buying time for sustained cooling and hazard assessment.

High-flow external cooling. Continuous water application aimed at the pack area (commonly ~100–500 GPM, per agency SOPs) reduces external temperatures and slows propagation, even though it cannot halt internal reactions. Use TIC to guide stream placement; avoid breaching sealed packs unless an OEM/FD procedure exists.

Engineering & tactical add-ons. Pack-level thermal barriers and directed vent paths (design stage) limit heat transfer; on scene, establish isolation distances, ventilate to dilute HF/CO, maintain SCBA, and monitor for re-ignition during salvage. For storage/ESS, add fire-resistant enclosures, gas detection, and automatic suppression compatible with UL 9540A findings.

For fire departments, this layered defense translates to clear actions: prevent (BMS integrity and pre-plan data), contain (EV blanket + exposure protection), and cool (sustained high-flow water with TIC and gas monitoring), followed by long-duration watch and separated post-incident storage.

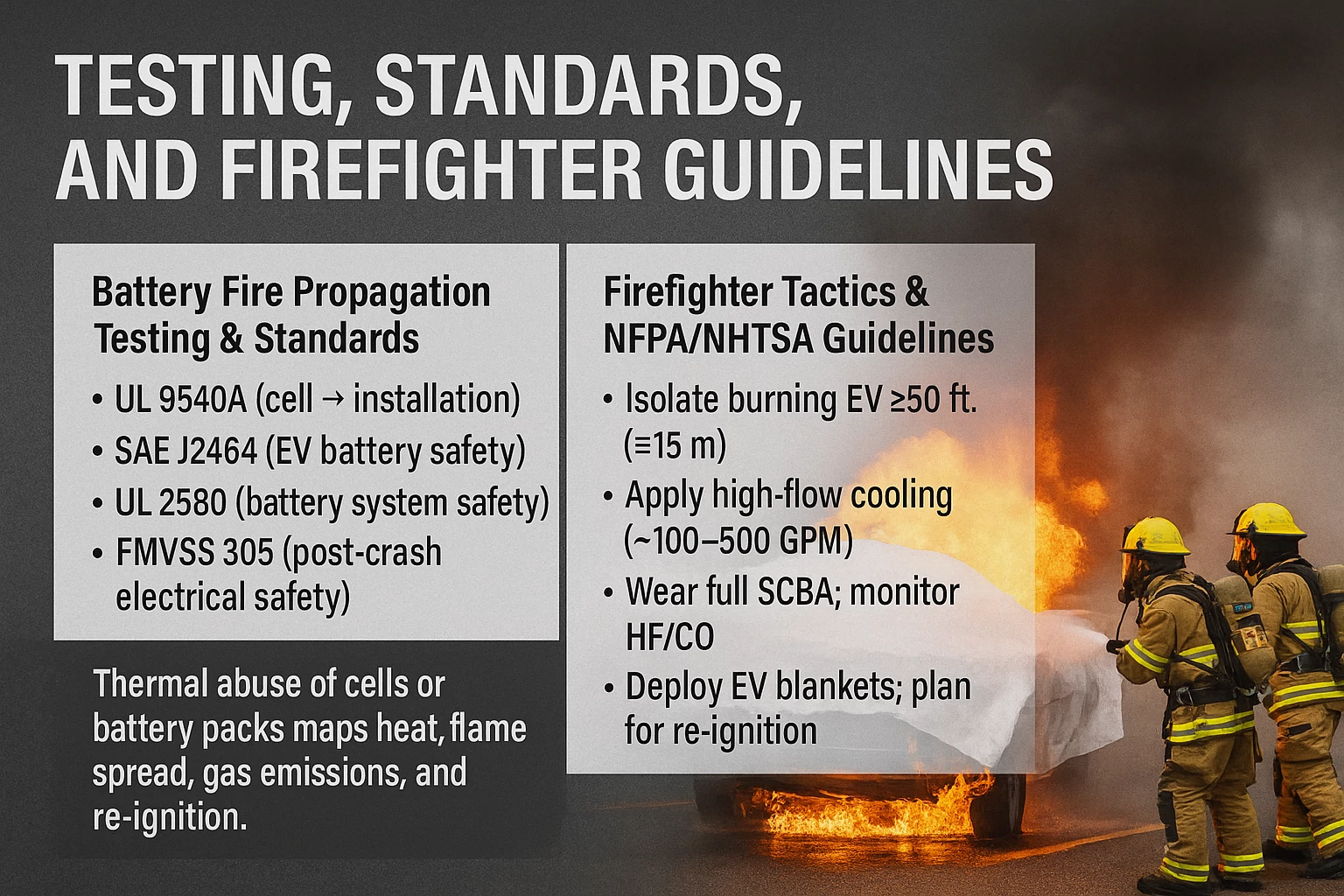

Testing, Standards, and Firefighter Guidelines

Battery fire propagation is characterized and quantified under rigorous test programs. UL 9540A (cell → module → unit → installation) and SAE J2464 (EV battery safety testing) subject cells and assemblies to thermal/electrical abuse to map heat release, flame spread, gas composition, and re-ignition behavior over time. For on-road EVs, UL 2580 (battery system safety) and FMVSS 305 (post-crash electrical safety) provide additional requirements for enclosure integrity, isolation, and fault response. Data from these protocols inform the design of thermal barriers, venting strategies, and thermal management systems, as well as pack segmentation, contactor logic, and diagnostics that reduce the likelihood and severity of propagation.

For firefighters and first responders, these findings translate into actionable tactics commonly reflected in NFPA/NHTSA guidance: establish an isolation perimeter of ≥50 ft (≈15 m) around a burning EV; apply high-flow external cooling (e.g., ~100–500 GPM, per local SOPs) directed at the pack area using TIC for stream placement; wear full SCBA and perform atmospheric monitoring for HF/CO; and anticipate “stranded energy”—residual charge capable of re-ignition up to ~24 hours after apparent knockdown. When flame and smoke need immediate containment, deploy EV fire blankets to reduce radiant heat, limit smoke spread, protect exposures, and provide critical time for tactical decision-making while sustained cooling and hazard assessment continue. Avoid breaching sealed packs unless following OEM/department procedures, and relocate the vehicle to a quarantined area ≥50 ft from exposures or maintain monitored watch for ≥24 hours. Lessons from real-world events (e.g., the 2019 Arizona ESS incident and multiple U.S. crash-involved EV fires reviewed by NHTSA) reinforce this layered approach: prevent with engineering and standards compliance, contain early at the scene, cool continuously, and monitor long after the flames are out.

Battery fire propagation is one of the most critical challenges in today’s electric vehicles (EVs). From the first spark in a single battery cell to full thermal runaway across a battery pack, the risks include extreme heat, toxic gases, and re-ignition long after flames are extinguished. Understanding its definition, process, threats, and standardized response protocols is vital for engineers, regulators, and especially for fire departments tasked with public safety.

At Safeprotex, we specialize in advanced EV fire blankets engineered to contain flames, limit smoke spread, and protect responders during these high-risk events. Connect with our expert team today to access reliable EV fire safety solutions and ensure your organization is prepared for the next challenge in lithium-ion fire safety.