Fire blankets work by quickly and effectively extinguishing early-stage fires through isolating the oxygen supply.Made from fire resistant materials, often as a sheet of woven fabric, fire blankets are widely employed in fire emergencies, such as smothering the flames of grease fires or protecting a person whose clothes have caught fire. In addition to their role in fire safety, fire blankets are versatile, durable, and easy to use, making them a critical part of any fire response plan.

In the United States, fire blankets are particularly valued for their compliance with international standards like EN 1869 and NFPA 701, as well as U.S.-specific certifications such as UL ratings. They complement other fire suppression tools, such as fire extinguishers, and are especially effective for use in homes, laboratories, and industrial environments. Fire blankets are categorized into two main types: Basic Material Fire Blankets and Composite Fire Blankets.

Types of Fire Blankets

Fire blankets come in various types, each designed for specific fire hazards. Basic fire blankets, made from lightweight fiberglass, are ideal for smaller household fires, such as kitchen grease fires or personal safety situations, withstanding temperatures up to 550°C (1,022°F). For industrial settings, high-temperature fire blankets made from high-silica fabric provide enhanced protection, handling temperatures up to 1,000°C (1,832°F), and are perfect for environments like welding or metalworking. For extreme conditions, such as electric vehicle fires or aerospace applications, graphite-coated fire blankets are designed to endure temperatures up to 1,100°C (2,012°F), offering superior protection in high-risk industries. Understanding the type of fire and choosing the appropriate blanket is crucial for effective fire suppression in critical moments.

Are Fire Blankets Effective?

Yes, fire blankets are highly effective — when used for the right types of fires.

Fire blankets work by smothering flames and cutting off the oxygen supply necessary for combustion. This makes them a fast, clean, and reliable tool to extinguish small fires, especially when dealing with flammable liquids or cooking fires. Fire blankets are particularly well-suited for Class A (solid combustible materials) and Class B (flammable liquids) — as defined by the National Fire Protection Association (NFPA) — though they should never be used on energized electrical equipment (Class C) or metal fires (Class D).

There are many types of fire blankets. Whether they are effective depends on the size of the fire in many cases. But in the final analysis, no matter what type of fire blanket (glass fiber, ceramic fiber, high silica, coated fire blanket, etc.), it is only suitable for small-scale fires, not large-scale or violent fires.

Usually, in an area of less than 1 square meter, the fire source is relatively concentrated, such as a grease fire within 3L, or in an environment such as a short circuit of household appliances, even an ordinary glass fiber fire blanket can quickly extinguish the fire.

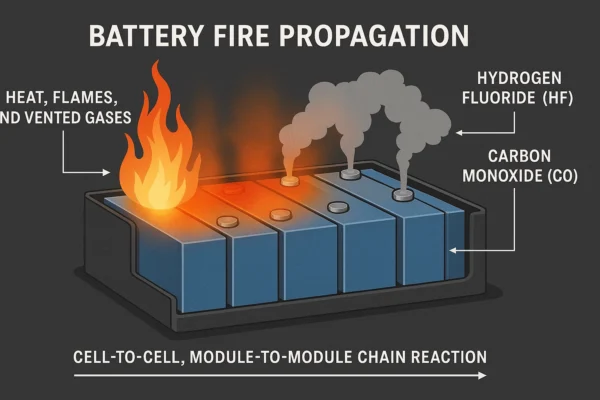

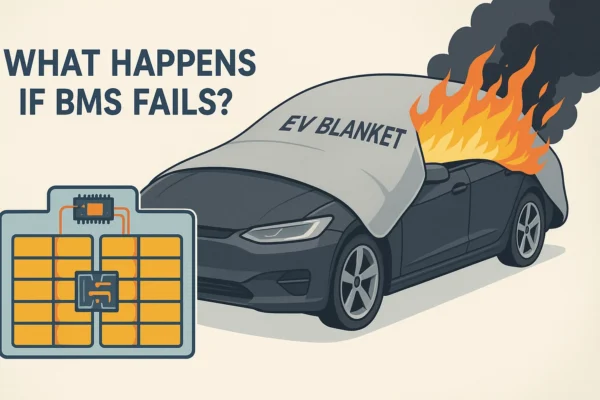

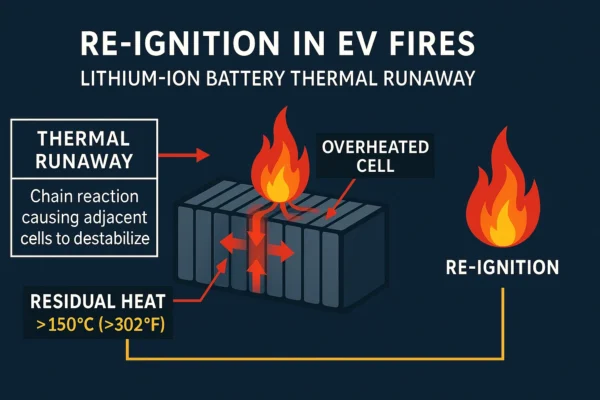

For special fires such as EV fires and lithium battery thermal runaway fires, high-performance silica fire blankets and coated fire blankets can also play a role in curbing and preventing the spread of fires (this type of fire can only be contained to prevent the fire from getting out of control)

More than 5 square meters, involving multiple rooms or areas, or caused by violently burning substances, such as a large amount of flammable liquid leakage, a large mechanical equipment fire, or a fire that spreads to the entire building, this type of fire requires a continuous water source or foam fire extinguishing system, usually requires large-scale firefighting equipment and professional firefighting teams to handle, and fire blankets cannot effectively extinguish.

How Much Heat Can A Fire Blanket Withstand

The heat resistance of a fire blanket depends on its material: fiberglass around 500–600 °C (932–1112 °F), silica fabric 1000–1200 °C (1832–2192 °F), and ceramic fiber up to 1400–1600 °C (2552–2912 °F). It’s important to distinguish continuous use from short-term exposure ratings. Standards typically test actual fire suppression performance rather than specify a single maximum temperature, so selection should match the intended use.

Best Uses for Fire Blankets

Cooking Fires (Grease Fires)

A fire blanket for kitchen use, such as a fiberglass fire blanket, is ideal for handling cooking fires, especially a grease fire where using water can cause violent flare-ups and oil splatter. Simply placing the blanket over a pot or pan cuts off oxygen and extinguishes the flames without spreading hot oil or leaving chemical residue. In a controlled test, a fire blanket for kitchen safety extinguished a burning grease fire at 400 °C (752 °F) in under five seconds.

Clothing Fires

If someone’s clothes catch fire, wrapping them in a fire blanket can quickly smother the flames. This technique is endorsed by first aid responders and is crucial in both home and workplace fire safety. Fire blankets are commonly found in labs, commercial kitchens, and classrooms for this reason.

Industrial & High-Temperature Environments

In industrial settings, fire blankets made from high-silica fabric or graphite-coated fiberglass offer protection in environments reaching temperatures of over 1,000°C (1,832°F). They’re used in welding operations, battery storage areas, and during hot work procedures to contain sparks and molten debris, reducing fire safety risks. In facilities handling lithium-ion batteries, fire blankets provide a critical layer of defense.

Where Fire Blankets Aren’t Effective

While excellent for extinguishing small fires, fire blankets are not effective for larger fires — such as those consuming entire rooms or involving complex electrical equipment(Especially EV fire). Fiberglass fire blankets should not be used on Class C (live electrical) or Class D (metal) fires, where specialized extinguishing agents are required.

In large-scale emergencies, a fire extinguisher, early evacuation, and contacting emergency services are essential. Think of fire blankets as first-response tools, not full replacements for a fire extinguisher.

Modern fire blankets are manufactured to comply with BS EN 1869:2019, the European standard for fire blankets, and many are also UL-certified in the United States. These certifications ensure performance under extreme heat and usability in real-life emergencies. As a result, fire blankets are widely trusted by homeowners, commercial kitchen operators, school districts, and RV owners for their fire safety needs.

Should You Have One?

Absolutely. A fire blanket is a low-cost, highly effective addition to your fire safety plan. Whether you’re frying food at home, managing tools in a workshop, or storing batteries in your garage, it offers fast, simple, non-toxic fire control that anyone can use — no training or mess required.

That’s why safety experts recommend keeping a fire blanket in every kitchen, vehicle, and workspace. If your home doesn’t have one yet, now is the time to add this essential tool to your fire safety kit.

Applications of Fire Blankets

Household Fires (Grease & Electrical Fires)

Fiberglass fire blankets are effective for Class A, B, and K fires, including grease and electrical fires. A fire blanket for kitchen is specially designed to handle cooking fires safely and quickly, helping reduce extinguishing time by up to 50% compared to standard fire blankets. Using a fire blanket for kitchen can prevent flare-ups and minimize damage during grease fires, making it an essential safety tool for any home or commercial kitchen.

Industrial Fires (Flammable Liquids & Combustible Metals)

For Class D (metal) and high-temperature fires, silica fire blanket withstand up to 1,000°C (1,832°F), while vermiculite-coated blankets protect against molten metal and welding sparks. These are commonly used in manufacturing, aerospace, and energy sectors.

Chemical Fires (Flammable Liquids)

Silicone-coated fire blankets resist chemical penetration, ensuring safe containment of flammable liquid fires in laboratories, chemical plants, and hazardous material storage.

Lithium Battery Fires

Graphite-coated silica fire blankets are designed for EV battery fires, tolerating 1,100°C (2,012°F) and slowing thermal runaway. They are essential for electric vehicle safety, battery storage, and logistics.

Extreme Fires (Aviation & Nuclear Applications)

Graphite-coated silica fire blankets maintain structural integrity for 15 minutes under intense mechanical and thermal stress, making them suitable for aircraft engine fire protection and nuclear safety shielding.

Selecting the right fire blanket depends on fire type, certification compliance (NFPA 701, UL 94 V-0, ASTM E84), and industry application.

| Type | Temperature Range | Applicable Scenarios | Key Features |

| Fiberglass Fire Blanket | 550°C (1,022°F) | Home kitchens, labs, vehicle fires | Cost-effective, portable, ideal for handling early-stage fires. |

| Silica Fire Blanket | 1,000°C (1,832°F) | Industrial equipment, high-temp pipes | High heat resistance, suited for industrial use. |

| Silicone Coated Fiberglass | 260-550°C (500-1,022°F) | Outdoor firefighting, chemical plants | Waterproof, oilproof, and chemical corrosion resistance. |

| Silicone Coated Silica | 1,000°C (1,832°F) | Aerospace, shipbuilding, nuclear sites | High mechanical strength, suitable for extreme temperatures. |

| Vermiculite Coated Fiberglass | 750°C (1,382°F) | Welding protection, spark barriers | Excellent flame impact resistance. |

| Vermiculite Coated Silica | 1,000°C (1,832°F) | Steel mills, high-temperature industry | Prolonged heat exposure resistance, strong thermal stability. |

| Graphite Coated High-Silica | 1,100°C (2,012°F) | Nuclear facilities, jet engines | Exceptional for extreme heat, excellent thermal conductivity and durability. |

Fire Blankets vs. Fire Extinguishers

Fire blankets and fire extinguishers serve distinct purposes. Fire blankets are effective for small, contained fires such as kitchen grease fires and clothing fires by smothering flames and cutting off the oxygen supply. In contrast, fire extinguishers, using chemical agents or CO₂, are necessary for larger or spreading fires, including electrical fires and flammable liquid fires, which can exceed 800°C (1,472°F).

For Class A, B, and K fires, fire blankets provide a residue-free, quick solution, making them ideal for homes, kitchens, and labs. Fire extinguishers (ABC, CO₂, dry chemical types) are essential for fuel-based and industrial fires. However, for EV fires, traditional extinguishers are ineffective due to thermal runaway. In these cases, only a specialized EV fire blanket can effectively contain flames, prevent gas spread, and isolate the fire until emergency responders arrive.

NFPA 10 and OSHA fire codes mandate properly maintained fire extinguishers in workplaces, while NFPA 701-certified fire blankets provide additional protection in areas with open flames or flammable materials. An NFPA 701 fire blanket meeting NFPA 701, FM 4950, and ASTM E84 standards helps protect against sparks, molten metal, and high heat. These certified fire blankets ensure reliable performance in demanding environments where safety is critical. For EV fires, high-temperature graphite-coated blankets are essential for containing fires above 1,100°C (2,012°F) and preventing toxic fume release.

Having both fire blankets and fire extinguishers ensures comprehensive fire safety, covering various fire hazards, including EV-related incidents.

How Does A Fire Blanket Work?

Fire blankets work by physically covering the fire source to cut off the oxygen supply, interrupting the combustion process. Their effectiveness is determined by the materials and coatings used, making them suitable for various fire scenarios. Below is a fully integrated summary of how different types of fire blankets operate.

Fire blankets made from fiberglass function by tightly adhering to the fire source to form a barrier that isolates oxygen while absorbing heat. Their flexibility allows them to adapt to irregular surfaces, making them ideal for putting out small fires, such as kitchen grease fires, withstanding temperatures up to 550°C (1,022°F). Enhanced with silicone coatings, they gain resistance to liquid flames and chemical corrosion, making them effective for grease and chemical fires. Silicone-coated blankets block liquid flames from penetrating the material while maintaining stability in temperatures from 260°C to 550°C (500°F–1,022°F).

For higher-temperature scenarios, high silica fire blankets excel in insulating and stabilizing fires involving industrial equipment or pipelines. Their low thermal conductivity reduces surrounding heat while maintaining integrity at up to 1,000°C (1,832°F). Adding a vermiculite coating makes these blankets resistant to molten debris and high-temperature sparks, ensuring protection in environments such as welding and cutting operations, where they withstand sparks as hot as 1,200°C (2,192°F).

In extreme fire situations, such as lithium battery or aviation engine fires, graphite-coated high-silica blankets combine high heat resistance and thermal conductivity to dissipate heat and prevent re-ignition. These blankets are designed to endure temperatures as high as 1,100°C (2,012°F) while maintaining physical integrity in high-pressure, dynamic environments.

Fire blankets, whether made from fiberglass, high-silica, or coated with silicone, vermiculite, or graphite, provide a versatile and efficient fire safety solution. Their ability to smother flames, resist liquid penetration, block sparks, and isolate high temperatures makes them indispensable for controlling and extinguishing fires across household, industrial, and extreme environments.

Are Fire Blankets A Good Idea?

If you need a quick and clean method to control fires close to a fire, a fire blanket is an essential fire safety tool. Designed to be simple and effective, fire blankets can put out a fire by smothering the flames and cutting off the oxygen supply without leaving chemical residues or damaging equipment like a fire extinguisher might.

Fire blankets are particularly effective for grease fires, where using water could cause splattering risks, or for welding sparks, where they shield nearby equipment from high heat. While both a fire blanket and fire extinguisher are valuable tools, fire blankets are ideal for situations requiring quick and localized action. Portable and easy to store, they can be hung on a wall or placed in a drawer for immediate access during emergencies.

Although not suitable for large-scale fires, fire blankets are trusted as the first line of defense for households and industries, offering a reliable, environmentally friendly, and practical solution to improve fire safety.

Ensure Your Fire Blanket Works When You Need It Most

A fire blanket is an essential fire safety tool that can help protect lives and property during emergencies. To ensure it performs effectively in critical moments, it’s important to select the right product, understand proper usage, and perform regular maintenance. Here’s a comprehensive guide:

Choosing the Right Fire Blanket

When selecting a fire blanket, consider the specific fire risks and protection needs of your environment:

Material Selection

- Fiberglass or Silicone-Coated Fire Blankets: Ideal for household scenarios, such as grease fires in kitchens or electrical fires.

- High-Silica or Vermiculite-Coated Fire Blankets: Suitable for high-temperature industrial fires or welding sparks.

- Graphite-Coated High-Silica Fire Blankets: Designed for extreme conditions, such as lithium battery fires, offering superior heat resistance.

- Certification Standards

Choose products that meet recognized safety certifications, such as EN 1869 (European standard) or NFPA 701 (U.S. standard), to ensure quality and reliability.

Size Selection

- For households, a 1m x 1m (39in x 39in) fire blanket is generally sufficient.

- For industrial settings, larger blankets (e.g., 2m x 2m) are recommended to handle larger fire sources.

How to Use a Fire Blanket

Proper use of a fire blanket is key to quickly controlling a fire and protecting yourself. Follow these steps:

Quickly Remove the Fire Blanket

Stay calm. Remove the fire blanket from its packaging and firmly hold two corners.Protect Yourself

Hold the blanket in front of you, using it as a shield to cover your hands and forearms. This helps protect you from burns when getting close to a fire.Cover the Fire Source

Approach the fire carefully from one side, and gently place the blanket over the flames. Ensure the fire is completely covered to cut off the oxygen supply.Press and Wait

Press the blanket down gently over the fire and hold it in place for 15–30 seconds to ensure the flames are extinguished.After the Fire is Out

Once the fire is extinguished, allow the blanket to cool before removing it. Check for re-ignition and call emergency services if needed.

Regular Inspection and Maintenance

To ensure your fire blanket is ready for use, regular inspection and proper storage are essential:

Inspection Frequency

Check your fire blanket every six months for signs of damage, such as tears, worn edges, or delaminated coatings. Follow the manufacturer’s guidelines, as fire blankets typically have a lifespan of 5–10 years.Storage Conditions

Store your fire blanket in a dry, accessible location, such as a wall-mounted pouch or drawer. Keep it away from corrosive chemicals and moisture to prevent degradation.Replacement

If the blanket shows signs of aging or damage, replace it immediately to ensure optimal performance during emergencies,some fire blankets are designed to be reused. Please follow the manufacturer’s instructions to determine whether fire blankets can be reused.

Fire blankets are a critical component of any comprehensive fire safety plan, providing a quick, effective, and clean solution for controlling early-stage fires. By smothering the flames and cutting off the oxygen supply, fire blankets prevent the spread of fires in both household and industrial environments. From grease fires in kitchens to high-temperature industrial fires or lithium battery hazards, the right fire blanket ensures protection for personnel, property, and lives. To maximize effectiveness, it’s essential to select certified products, maintain them regularly, and use them correctly during emergencies.

For over a decade, Safeprotex has been a leader in designing and manufacturing high-performance fire blankets. With rigorous certifications such as those required for an NFPA 701 fire blanket and EN 1869, Safeprotex products meet the highest international standards for safety and reliability. Whether you’re safeguarding your home or workplace, Safeprotex fire blankets combine advanced materials, such as high-silica and graphite coatings, with expert design to provide superior protection.

Protect what matters most with Safeprotex fire blankets! Contact Safeprotex today for expert guidance, customized fire safety solutions, and competitive wholesale pricing. Don’t wait until it’s too late—ensure the safety of your loved ones, employees, and assets now!