The rapid adoption of electric vehicles (EVs) has introduced new fire safety challenges, particularly when it comes to lithium-ion battery fires. For instance, a 2021 study reported over 50 major EV fire incidents globally, highlighting the risks associated with battery failures. EV fires are complex, hazardous, and require specialized tools, such as EV fire blankets, to put out EV Fires. However, the lack of standardized testing and certifications across the EV blankets industry creates confusion and safety risks for customers.

EV Fires Create New Problems

EV fires differ from traditional vehicle fires in ways that demand tailored solutions:

- Thermal Runaway: A single lithium-ion cell failure can initiate a chain reaction, known as thermal runaway, where adjacent cells ignite uncontrollably. This process produces extreme temperatures, often reaching 1,200–1,400°C, and leads to repeated EV fire outbreaks.

- Prolonged Burning: Lithium ion battery fires can smolder for hours and reignite after appearing extinguished due to residual heat within the battery pack.

- Toxic Gas Emissions: Fires involving lithium-ion batteries release harmful gases, including hydrogen fluoride (HF) and carbon monoxide (CO), which pose significant health risks.

Incompatibility with Water Traditional firefighting methods, such as water or foam, are often ineffective against electric vehicles evs fires because lithium-ion batteries generate intense heat and toxic emissions during combustion. Unlike traditional vehicle fires, which can be extinguished relatively quickly with water or foam, EV fires require an overwhelming amount of water—often tens of thousands of liters—to sufficiently cool the batteries and prevent reignition. This makes multi use blankets a more practical and efficient alternative for reduce the risk,smothering fires, isolating toxic emissions, and minimizing damage.

Why Standards Are Necessary

Current Issues

Fragmentation: The EV fire blanket industry lacks unified safety standard, resulting in inconsistent EV blankets performance and certification processes.

Customer Confusion: Without clear benchmarks, buyers struggle to compare products based on claims like heat resistance, durability, and fire containment.

Safety Risks: Poorly manufactured or untested electric vehicle fire blankets can fail during real-life emergencies, endangering users and property.

Unified standards are crucial to ensure product reliability, build customer trust, and comply with fire safety regulations across various applications, including EV storage and public safety. The absence of a clear standard for EV blankets has resulted in instances where customers unknowingly purchase fire blankets that fail under extreme conditions. These failures, such as blanket tears during deployment or inadequate thermal resistance leading to reignition, have been documented in several cases. Such incidents highlight the urgent need for reliable, standardized products to ensure safety, particularly in vehicle fires.

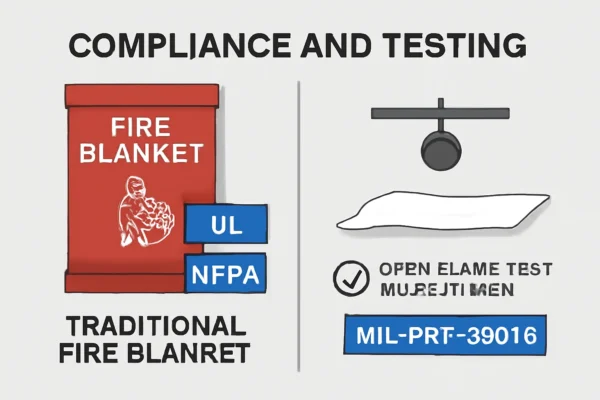

Standards for EV Fire Blankets

When navigating the complexities of vehicle fire safety, several well-established standards provide clear guidelines for assessing the performance and reliability of fire blankets. These key standards for EV blankets set the benchmarks for testing and certifying electric vehicle fire blankets, ensuring they meet the required safety and performance criteria.

DIN SPEC 91489:2024-11

DIN SPEC 91489:2024-11 is a German standard specifically developed for evaluating the performance and testing methods of fire blankets designed for electric vehicles (EV). It is the world’s first standard focused on EV fire mitigation, providing a unified framework for assessing the performance of fire blankets.

DIN SPEC 91489 outlines comprehensive testing protocols, covering high-temperature resistance, mechanical stability, and chemical durability. The standard specifies testing methods and qualification criteria to ensure fire blankets are safe and reliable in high-temperature scenarios.

Testing Methods:

According to DIN SPEC 91489, fire blankets must undergo a series of rigorous tests under extreme conditions, including:

- High-Temperature Exposure Test: The fire blanket must endure heat radiation up to 1200°C (2192°F), simulating an EV battery thermal runaway scenario.

- Mechanical Strength Test: Verifies whether the fire blanket can maintain its structural integrity when deployed over a vehicle, especially during the initial intense fire conditions.

- Chemical Resistance Test: Assesses the fire blanket’s ability to resist corrosive gases and liquids released during an EV battery fire.

Fire blankets that meet the standard must achieve the following benchmarks:

- Effectively isolate flames and heat radiation for more than 15 minutes.

- Maintain structural integrity without significant damage or melting during the test.

- Demonstrate resistance to corrosive substances, such as hydrofluoric acid, emitted during EV fires.

DIN SPEC 91489 is a significant milestone in the industry. It provides manufacturers with clear design and testing guidelines and builds customer confidence in the performance of electric vehicle fire blankets. While primarily adopted in the European market, the rigorous testing methods and technical requirements are gradually being recognized worldwide, offering a benchmark for global EV fire safety solutions.

NFPA 701

The NFPA 701 standard, developed by the National Fire Protection Association (NFPA), is designed to assess the flame resistance of textile materials. It comprises two primary testing methods. Test Method 1 applies to fabrics weighing less than 700 g/m² (20.6 oz/yd²), while Test Method 2 is used for heavier and more robust fabrics. Given that EV fire blankets are typically constructed from thick, heat-resistant textiles, they are generally tested using Test Method 2.

NFPA701 Fire Blanket Requirements:

For Test Method 2, the EV fire blanket is suspended, and the lower edge of the sample is exposed to a direct flame for 12 seconds. To pass the test, the material must meet the following performance criteria:

- The flame propagation rate across the sample surface must not exceed 3.5 ft/s (1.07 m/s).

- The flame must self-extinguish within 2 seconds of the flame source being removed.

- The char length, defined as the visibly damaged or brittle area on the material, must not exceed 10 inches (25.4 cm).

- The material must not produce any flaming drips during the test.

- The total area affected by burning or charring must remain below 5% of the sample’s total area.

While NFPA 701 provides a reliable baseline for evaluating flame resistance, its testing conditions do not fully replicate the extreme scenarios associated with EV battery thermal runaway, where temperatures can exceed 2192°F (1200°C). To address these limitations, the following supplementary tests are recommended:

1. Thermal Radiation Exposure

- Simulated temperature: 1832°F to 2192°F (1000°C to 1200°C).

- Exposure duration: Minimum of 30 minutes.

2. LPTP (Large Pool Fire Test Protocol)

- Fire scenario: Simulating large-scale fires with sustained combustion exceeding 15 minutes.

- Evaluation criteria: The structural integrity and containment capabilities of the fire blanket under prolonged high-temperature exposure.

By combining NFPA 701 with these advanced testing methodologies, manufacturers can ensure that EV fire blankets meet the rigorous demands of real-world applications, providing superior safety and reliability in critical fire containment scenarios.

NFPA 855

While primarily focused on energy storage systems (ESS), this U.S. standard provides essential fire safety guidelines relevant to EV fires.

NFPA855 Fire Blanket Requirements:

Thermal Propagation Mitigation: Verifies the blanket’s ability to smother flames and control thermal runaway. For instance, certified blankets reduced thermal propagation by 85% in simulated battery fire scenarios.

Toxic Gas Emission Control: Assesses how effectively the blanket contains hazardous gases. During testing, certified blankets reduced hydrogen fluoride emissions by 70%, significantly lowering health risks.

Confined Space Testing: Simulates deployment in parking garages or warehouses to validate fire containment in enclosed areas. In confined space tests, certified blankets demonstrated a 90% containment rate of fire spread and toxic gases.

Significance: NFPA 855 is crucial for applications like EV parking facilities, transport companies, and public safety agencies, addressing risks associated with confined spaces and large-scale EV storage.

While primarily focused on energy storage systems (ESS), this U.S. standard provides essential fire safety guidelines relevant to EV fires.

BS EN 1869/ISO 11612:2015

BSI (British Standards Institution) is the UK’s national standards body, providing multiple standards related to the performance evaluation of fire blankets. While there are no BSI standards specifically for electric vehicle fire blankets, the following methods and criteria are commonly used to evaluate general fire blanket performance

Key Test Methods:

BS EN 1869:1997

This standard applies to lightweight and heavy-duty fire blankets, assessing their performance in small fire scenarios. Key test focuses include:- Coverage Performance: Verifies the fire blanket’s ability to completely cover the fire source and block oxygen supply.

- High-Temperature Resistance: Tests the material’s durability when exposed to open flames (up to 600°C / 1112°F).

BS EN ISO 11612:2015

This standard evaluates materials’ protective abilities in extreme heat, with exposure temperatures reaching 1000°C (1832°F). Key aspects include:- Thermal Conductivity: Measures the fire blanket’s ability to block heat transfer.

- Mechanical Integrity: Checks whether the material cracks or melts under high temperatures.

Compliance Indicators:

- After 15 seconds of covering the fire source, oxygen isolation must exceed 99%.

- At 600°C (1112°F), the material must not melt, break, or ignite.

- The fire blanket must resist short-term high heat radiation (up to 1000°C / 1832°F) without structural damage.

LPTP

LPTP (Large Pool Fire Test Protocol) is a testing protocol designed for large-scale fire scenarios, commonly used to evaluate fire suppression equipment’s performance in extreme fire conditions, particularly in the petrochemical industry. For electric vehicle fire blankets, LPTP testing methods simulate large fires caused by battery thermal runaway.

Key Test Methods:

- High-Temperature Fire Simulation:

A large fuel pool fire with a diameter of approximately 3 meters (10 feet) simulates a high-intensity fire, with flame temperatures typically exceeding 1200°C (2192°F). - Fire Source Coverage Test:

The fire blanket must fully cover the fire source when deployed, assessing its ability to suppress flames and block heat radiation. - Sustained Burn Test:

The fire blanket is tested under continuous fire exposure for 15 minutes, evaluating its structural integrity and material performance.

Compliance Indicators:

- Flame Isolation: The fire blanket must prevent flames from spreading outside the covered area, achieving an isolation rate of at least 95%.

- Thermal Resistance: The temperature on the underside of the fire blanket must not exceed 150°C (302°F) to ensure safety outside the fire zone.

- Material Integrity: After 15 minutes of high-temperature exposure, the fire blanket must not melt, crack, or lose functionality.

Additional Relevant Standards

OSHA Fire Blanket Requirements: OSHA establishes fire protection regulations but does not directly certify fire blankets. However, fire blankets play a critical role in workplace fire safety, aligning with OSHA 1910.157 (Fire Extinguishers), OSHA 1910.39 (Fire Prevention Plans), and OSHA 1910.252 (Welding Safety).

To meet OSHA guidelines, fire blankets used in welding zones, manufacturing plants, and emergency fire suppression should comply with industry-recognized standards such as NFPA 701, FM 4950, and ASTM E84. While OSHA does not mandate these certifications, they are considered best practices for ensuring workplace fire safety.

Employers are responsible for assessing fire risks, implementing proper fire protection tools, and ensuring fire blankets are part of a broader fire safety strategy. Non-compliance with OSHA fire protection regulations can result in penalties exceeding $15,000 per violation, making adherence to recognized fire safety standards essential for workplace safety.

EN 13501-1: Evaluates the fire behavior of materials, ensuring blankets do not contribute to flame spread or produce excessive smoke. Certified materials achieved a Euroclass A2 rating, confirming their limited combustibility and low smoke production.

ISO 22899-1: Tests blankets under high-intensity jet fire conditions, simulating concentrated flame exposure. Certified blankets withstood jet flames of 1,300°C for 20 minutes without compromising integrity.

ISO 6940/6941: Assesses the ignitability and flame spread characteristics of the fabric used in fire blankets. Testing showed that certified fabrics delayed flame spread beyond 12 seconds, meeting ISO standards for fire-resistant textiles.

Is It Enough To Rely Solely On Standards?

Although standards can ensure the minimum threshold for fire blankets, it is not entirely correct to rely solely on standards to determine which fire blanket to purchase. There are some high-performance flame-retardant blankets in conventional fire blankets, such as high-silica fire blankets and ceramic fiber fire blankets, which also have strong high temperature resistance and flame retardant properties. However, ordinary fire blankets that have not been coated will begin to have airtightness problems when facing a large amount of toxic gases generated by EV Fire. At present, most of the certifications for electric vehicle fire blankets are basically for flame retardancy and material strength tests, and there is no sufficient consideration for airtightness. Therefore, it is extremely dangerous to use regular fire blankets that meet the above standards to extinguish EV Fire.

In addition, during the EV fire process, the hot air flow will lift the fire blanket upward. In response to this situation, professional EV blankets will be equipped with cables to ensure that the blanket is completely fixed, while ordinary fire blankets do not have this function.

A Case for Standardized Fire Blankets

In 2023, a fire in an EV storage warehouse in Germany caused over $10 million in damages and required several days to fully extinguish due to the lack of adequate fire containment measures. Without a certified fire blanket, similar incidents could lead to catastrophic fires, endangering lives and property. By investing in a blanket certified to DIN SPEC 91489, the facility ensures:

- Fires are quickly contained.

- Toxic emissions are isolated, protecting workers.

- Compliance with fire safety regulations is maintained.

Such scenarios highlight the importance of choosing products that meet rigorous standards, ensuring preparedness for worst-case situations.

As EV technology evolves, the need for robust safety solutions becomes critical. Fire blankets certified to rigorous standards like DIN SPEC 91489 and NFPA 701 exemplify this advancement by addressing modern challenges in EV fire safety. These standards not only address the complex challenges of EV fires but also set a clear benchmark for performance, safety, and trust.

For example, products certified under DIN SPEC 91489 undergo rigorous fire resistance and tear strength tests, ensuring they perform reliably in real-world scenarios and build customer confidence in their effectiveness. By choosing certified products, businesses and individuals can ensure they are prepared for the unique risks posed by EV fires—such as thermal runaway or toxic gas emissions—protecting lives, property, and the environment.

At Safeprotex, you can choose high-performance EV fire blankets that meet DIN and NFPA certifications. In addition to certifications, our experienced professional team has also mastered the most effective thermal runaway fire protection solutions through hundreds of experiments. Talk to our experts and let us help you solve your EV fire problems.