How do you ensure that the fire blankets you purchase won’t fail when it matters most? In the fire safety industry, procurement mistakes can lead to regulatory fines, product recalls, and serious liability risks. Unlike consumer purchases, fire blanket procurement requires strict adherence to NFPA 701, UL 214, and ASTM D6413 standards, along with batch-to-batch quality consistency. A single non-compliant product in your inventory could compromise safety certifications, damage your brand’s reputation, or even result in legal action.

Despite these risks, structured procurement guidance in this field remains scarce. Many companies rely on standard procurement checklists, but when it comes to fire protection, a generic checklist isn’t enough. That’s why Safeprotex, a fire blankets manufacturer with over a decade of experience in fire safety product development, is providing this comprehensive guide. By the end of this article, you’ll understand how to evaluate suppliers, verify compliance, and source fire blankets that meet both regulatory and operational safety standards—without costly mistakes.

Beyond Certification

A fire blanket is fundamentally composed of a fire-resistant base fabric and, in many cases, a coating layer that enhances durability and resistance to external factors. Some high-performance models also incorporate reinforced stitching, using Kevlar® or stainless steel threads, to withstand prolonged exposure to extreme heat and mechanical stress. While certifications such as FM 4950 confirm fire resistance for welding applications, they do not account for long-term wear, material degradation, or cost-effectiveness in real-world industrial settings.

A comparative study conducted under ASTM D6413 (Vertical Flame Test) and ISO 9151 (Heat Transfer Performance Test) showed that uncoated fiberglass fire blankets lost structural integrity up to 5 times faster than silicone-coated alternatives when subjected to continuous high-temperature welding slag exposure (1300°F / 704°C) for extended periods. The uncoated fiberglass material exhibited fiber breakage and rapid fraying within 24 hours, whereas the silicone-coated fire blankets maintained their protective integrity for at least 10–14 days under the same conditions.

Safeprotex’s own manufacturing and field data further support this: industrial users who switched from fiberglass to silicone-coated fire blankets reported a 70% reduction in replacement frequency, significantly lowering their annual procurement costs. This aligns with operational feedback from heavy-duty welding facilities, where coated blankets provide superior abrasion resistance, slag deflection, and moisture protection, reducing downtime and material waste.

While FM 4950 certification ensures that a fire blanket meets fundamental fire resistance requirements, procurement managers must also consider factors such as supply chain reliability, batch-to-batch consistency, and long-term performance under operational stress. A certified fire blanket that requires frequent replacement may lead to unexpected costs, logistical inefficiencies, and compliance risks. To optimize procurement decisions, buyers should go beyond certifications and evaluate how material composition impacts longevity, maintenance, and overall operational efficiency.

Base Fabric Breakdown

The base fabric of a fire blanket significantly impacts fire resistance, durability, and cost-effectiveness. Among the most commonly used materials, fiberglass and high-silica fabric stand out, but their performance is heavily influenced by material purity and manufacturing processes.

A critical yet often overlooked factor is the fuel source used in molten glass production. Manufacturers primarily use heavy oil or liquefied petroleum gas (LPG), and this choice directly affects fiber purity, strength, and flame resistance:

- Heavy oil-based melting results in higher impurities, reducing flame penetration resistance and fiber durability.

- LPG-based melting, though more costly, produces high-purity fiberglass, ensuring greater fire resistance and extended lifespan under extreme heat.

To ensure superior fiberglass quality, Safeprotex sources 99.7% purity LPG from Mont Belvieu, Texas, one of the most advanced LPG refining hubs globally. With minimal sulfur content (<1 ppm), it eliminates structural defects common in lower-grade fiberglass, while ASTM D2713-compliant moisture levels (<10 ppm) prevent fiber brittleness. Industry tests show that fiberglass made with Mont Belvieu LPG achieves 35% longer flame exposure resistance in ASTM D6413 tests and maintains thermal stability at 1200°F (648°C) for twice as long compared to heavy oil-melted fiberglass.

Despite these benefits, over 60% of global fiberglass manufacturers still rely on heavy oil due to cost constraints, leading to higher defect rates and increased replacement cycles. For procurement managers, ensuring batch consistency and supplier reliability is crucial. Requesting ASTM C165 compression test reports and ISO 1887 purity certifications helps verify material quality and long-term durability.

Safeprotex uses EN 1869-certified high-silica fabric, UL 94 V-0 silicone-coated fiberglass/high-silica fabric, vermiculite-coated fiberglass/high-silica fabric, and graphite-coated high-silica fabric, ensuring high heat resistance and fire protection.

Weaving Structure

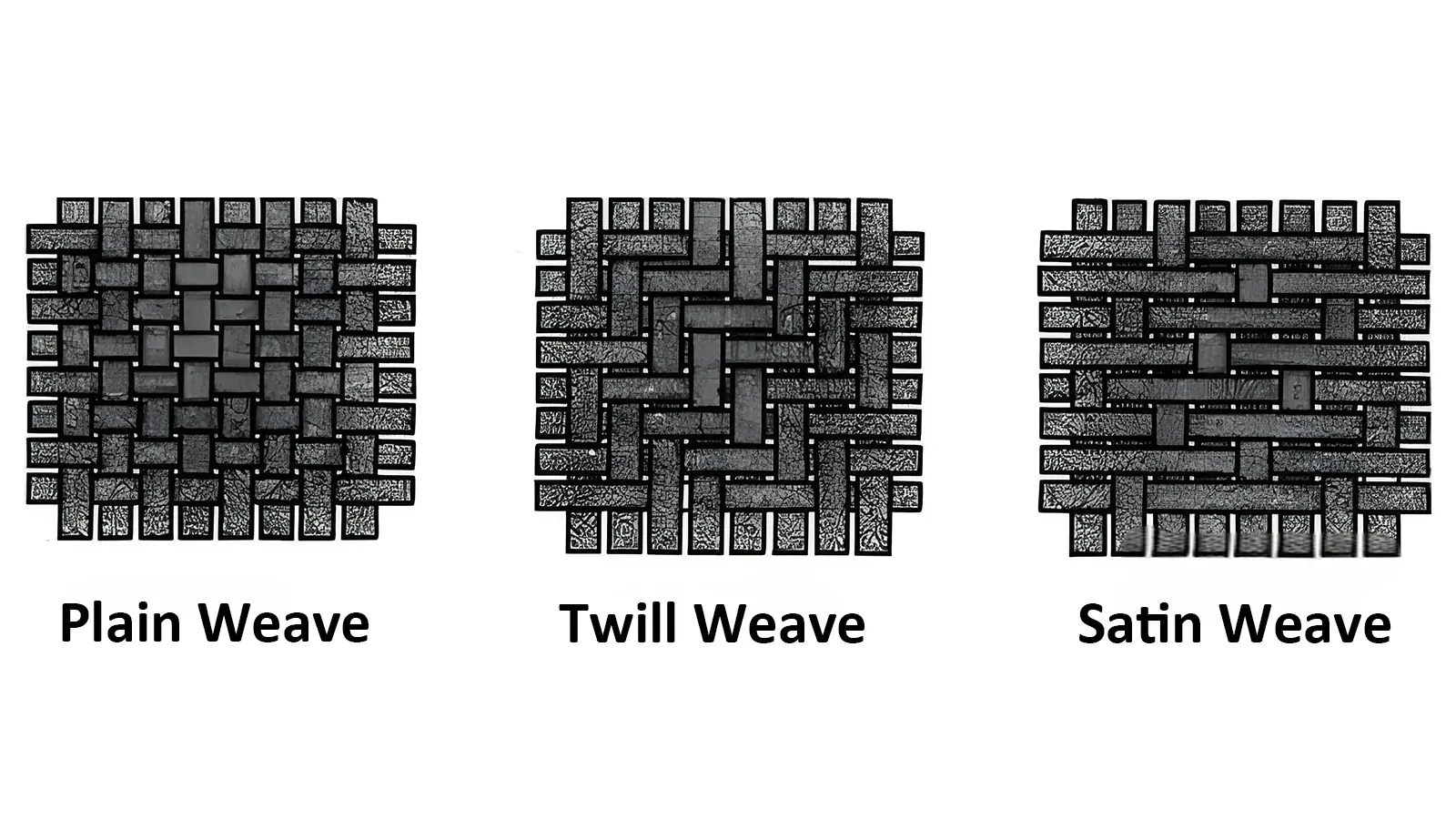

Fabric weave directly affects tensile strength, flexibility, and heat resistance:

| Property | Plain Weave | Twill Weave | Satin Weave |

| Strength | High | Medium | Low |

| Flexibility | Low | Medium | High |

| Heat Resistance | High | Medium | Low |

| Recommended Use | Heavy-duty industrial blankets | General fire protection | Flexible applications |

Plain weave provides maximum durability for industrial fire protection, while satin weave, though flexible, is less resistant to mechanical wear.

For buyers, selecting the right fire blanket requires more than just checking certifications. The source of fiberglass, weaving structure, and supplier consistency play a critical role in overall performance. While LPG-melted fiberglass lasts up to 40% longer in high-temperature conditions, ensuring quality verification through ISO 1887 purity reports and ASTM C165 test results is essential. Regional supply chain differences also impact pricing and availability, making long-term sourcing strategy a key factor in cost efficiency. Prioritizing material purity and supplier reliability ensures both enhanced fire protection and reduced operational costs.

Coatings

Fire blanket coatings serve a critical function beyond the base fabric, increasing thermal resistance, flame penetration resistance, and environmental durability. Coatings also improve waterproofing, oil resistance, chemical stability, and weather durability, making them essential for industrial and fire protection applications. The most common fire-resistant coatings include silicone, acrylic, vermiculite, and graphite, each providing distinct performance characteristics.

The choice of coating material directly impacts the fire blanket’s performance under heat and mechanical stress. Below is a breakdown of the most common coatings:

| Coating Type | Max Temperature Resistance | Key Advantages | Common Applications |

| Silicone | 250°C (482°F) | High flexibility, excellent weather resistance, maintains adhesion after multiple fire exposures | Welding protection, high-temperature environments |

| Acrylic | 180°C (356°F) | Cost-effective, chemical-resistant, but less durable under prolonged heat exposure | Light-duty fire blankets, oil and chemical spill control |

| Vermiculite | ≥1000°C (1832°F) | Extreme heat resistance, forms protective char layer, but more brittle | Foundry, metallurgy, and high-temperature shielding |

| Graphite | 500°C (932°F) | Electrically conductive, enhances thermal insulation, reduces oxidation damage | Aerospace, high-temperature insulation |

The effectiveness of a fire-resistant coating depends not only on the base material but also on the flame retardant additives used. These additives influence oxygen index (LOI), thermal stability, and smoke release levels.

- Halogen-based retardants – Provide excellent flame suppression but raise environmental concerns.

- Inorganic retardants (Aluminum Hydroxide, Magnesium Hydroxide) – Release water vapor at high temperatures, slowing flame spread.

- Phosphorus-based retardants – Enhance char formation, reducing heat penetration.

- Silicone-based retardants – Offer superior high-temperature resistance without toxic byproducts.

Coatings with an LOI ≥ 30% (ASTM D2863) are considered self-extinguishing, a key requirement for high-performance fire blankets.

Coating Process

The coating process affects adhesion, thickness, and durability.

| Coating Method | Thickness Range | Advantages | Recommended Use |

| Knife Coating | 100–2,000 µm (0.004–0.08 in) | Thick, uniform application, excellent heat resistance | Heavy-duty industrial fire blankets |

| Impregnated Coating | 50–500 µm (0.002–0.02 in) | Deep fiber penetration, maintains flexibility | Lightweight and flexible fire blankets |

| Roller & Spray Coating | 25–300 µm (0.001–0.012 in) | Even coating, cost-effective, but lower fire resistance | General-purpose coatings, low-heat applications |

| Casting Coating | 500–2,000 µm (0.02–0.08 in) | High-density coating, best adhesion, superior durability | High-temperature industrial protection |

One of the lesser-known but significant risks in low-cost fire blankets is the use of reprocessed or recycled coating materials. Some manufacturers reuse spent coatings, melting them down and reapplying them to fabric. This cost-cutting measure results in poor adhesion, reduced flame resistance, and premature failure. Fire blankets using such coatings often harden, crack, and peel off under heat exposure, leaving the base fabric unprotected. In contrast, virgin polymer coatings maintain their structural integrity, ensuring long-term durability and superior fire resistance.

For buyers, selecting the right fire blanket requires more than just checking certifications. The coating material, flame retardant formulation, and application process play critical roles in durability and fire performance. Silicone coatings consistently outperform acrylic coatings in high-temperature applications, but procurement managers must weigh cost versus longevity when making sourcing decisions.

Beyond material selection, quality verification is essential. Industrial-grade fire blankets should have a coating adhesion rating of ≥5B (ASTM D3359) and a peel strength of ≥10 N/cm (57 oz/in) to ensure they can withstand mechanical stress and prolonged heat exposure. To prevent performance degradation, buyers should request ISO 1887 purity certifications and ASTM C165 compression test reports to confirm that coatings are made from high-quality virgin materials rather than reprocessed compounds.

By prioritizing high-purity coatings, verifying supplier batch consistency, and selecting the appropriate application method, buyers can ensure long-term fire protection and reduced operational costs.

What Technical Parameters You Should Focus On?

Fire blankets vary widely in their applications, and while their specifications may seem similar, the right technical parameters make all the difference in performance and safety. Choosing a blanket solely based on certifications without considering application-specific requirements can lead to inefficient protection and increased risk.

For kitchen fires, the priority is quick and effective flame suppression. Fiberglass fire blanket should withstand temperatures of at least 500°C (932°F), completely smother flames within 10–15 seconds (ASTM F1989), and feature non-adhesive, oil-repellent properties to prevent reignition. Ease of handling and quick deployment are also critical in emergency situations.

In welding applications, where welding fire blankets must block molten metal splatter and sparks, the key factors are flame penetration resistance (LOI ≥30%, ASTM D6413) and high-temperature tolerance (ISO 9185, up to 1400°C / 2552°F). The material should self-extinguish within 2 seconds after flame exposure (ISO 15025) and offer high abrasion resistance to withstand frequent repositioning in industrial settings.

For EV battery fires, blankets must endure prolonged exposure to extreme heat while also containing toxic fumes. Performance depends on heat endurance time (≥30 minutes at 1200°C, ASTM E119) and gas containment efficiency (ASTM E2067). Given their high cost, reusability is an important factor for long-term cost efficiency.

Beyond these core performance indicators, material quality plays a crucial role in durability. Some manufacturers use reprocessed coatings, which crack and peel under extreme temperatures, leaving the fabric exposed. High-purity virgin coatings ensure better adhesion, longer heat resistance, and reliable performance over multiple uses.

When assessing specifications, it’s essential to verify testing standards rather than relying on surface-level certifications. Safeprotex follows ASTM and ISO standards, ensuring coating adhesion strength (≥5B, ASTM D3359), peel resistance (≥10 N/cm, ASTM C165), and gas containment reliability (ASTM E2067). By prioritizing the right parameters and verifying supplier consistency, buyers can maximize fire protection effectiveness and optimize long-term costs.

The Right Manufacturer

As a fire blanket manufacturer, Safeprotex understands that production consistency, certification compliance, and supply chain stability are crucial in supplier selection. Even minor variations in coating thickness, tensile strength, or flame penetration resistance can impact safety. Safeprotex ensures batch-to-batch consistency with ISO 9001-certified process controls, automated production lines, and rigorous flame resistance and tensile strength testing, maintaining an industry-leading defect rate of <0.5%.

Certifications demonstrate a manufacturer’s commitment to quality and regulatory compliance. Safeprotex fire blankets hold NFPA 701, UL 94 V-0, ASTM E84, EN BS 476, and FM 4950 certifications, ensuring compliance with U.S., European, and industrial fire safety standards. These certifications validate flame resistance, smoke suppression, and self-extinguishing properties, while ISO 14001 compliance reflects our commitment to sustainable manufacturing.

Supply chain reliability is essential for consistent delivery and material availability. Safeprotex maintains a 95%+ on-time delivery (OTD) rate, leveraging multi-source raw material procurement and regional distribution hubs to prevent disruptions. Even during Q1 2024’s industry-wide raw material shortages, Safeprotex ensured uninterrupted production for our clients.

Customization is another key factor in selecting a manufacturer. Safeprotex provides engineering customization, optimizing coating thickness, flame-retardant formulations, and reinforcement layers to meet specific industry needs. A U.S. aerospace client saw a 15% improvement in thermal barrier performance after switching to Safeprotex’s high-purity silicone-coated fire blankets.

To ensure quality and reliability, buyers should verify certifications, request batch test reports (ASTM D6413, ISO 9185, ASTM E2067), and assess supply chain stability. Choosing a certified, quality-driven manufacturer like Safeprotex minimizes procurement risks and ensures reliable, high-performance fire protection solutions.

For companies procuring fire blankets, bulk supply is essential, but true value lies in reliability during emergencies. Many suppliers claim compliance, yet inconsistencies in coating thickness, flame penetration resistance, and thermal endurance remain common. Selecting a manufacturer with certified safety standards, batch-to-batch consistency, and proven performance is critical.

At Safeprotex, we reinvest 32% of our profits into R&D, continuously refining coating formulations, fabric integrity, and fire resistance technology. Our NFPA 701, UL 94 V-0, ASTM E84, EN BS 476, and FM 4950-certified blankets undergo strict testing to ensure verified durability and real-world effectiveness.

Procurement teams should demand third-party test reports, verify UL compliance, and assess process controls—key factors Safeprotex integrates into every order. When fire safety is at stake, choosing a manufacturer with proven fire protection technology is not optional—it’s essential.

References

- Heaterk. (2022). Flame Retardants in Coated Fiberglass Fabrics.

- Heaterk. (2024). Impact of Coating Processes on Silicone-Coated Fabric Performance.

- Heaterk. (2023). Differences Between Weaving of Fabrics.

- Heaterk. (2023). What is Fiberglass?.

- National Fire Protection Association (NFPA). (n.d.). NFPA Codes and Standards.

- Horrocks, A. R., & Kandola, B. K. (2004). Flame Retardants in Commercial Use or Development for Textiles.

- MDPI Polymers. (2022). Flame Retardant Coatings: Additives, Binders, and Fillers.