What happens when a single spark lands where it shouldn’t?

Welding is a cornerstone of modern industry. From automotive plants and oil refineries to shipyards and aerospace hangars, the welding process is performed in high-risk environments every day. At the heart of this process is extreme heat—arc temperatures can soar beyond 10,000°F (5,500°C). It also produces molten metal, slag, and sparks that can shoot more than 35 feet, landing unpredictably on surrounding areas.

These conditions are not just dangerous—they’re costly. According to the National Fire Protection Association (NFPA), hot work operations like welding, cutting, and grinding cause an average of 4,580 structure fires annually in the United States. These fires result in over $484 million in property damage, 171 civilian injuries, and 22 deaths each year. A notable case in 2021 saw sparks from routine welding ignite roof insulation in a manufacturing facility, causing a fire that spread across 20,000 square feet in under 10 minutes.

Many of these incidents are entirely preventable—with the right safety equipment in place.

That’s where welding blankets come into play. These flame retardant covers are designed to protect nearby people, machinery, and workspaces from sparks, slag, and molten metal. Made from heat resistant materials, each fire blanket serves as a physical barrier, shielding surrounding areas from high-temperature exposure. Whether you’re a welder, a plant supervisor, or a safety officer, understanding how welding blankets work—and how to choose the right FM Approvals-certified solution—can make the difference between a job well done and a costly disaster.

What Is a Welding Blanket?

A welding blanket is a flame-resistant safety barrier used to shield workers, equipment, and nearby surfaces from sparks, slag, molten metal, and radiant heat during welding or cutting. Unlike personal protective gear, it’s a stationary layer made from heat-resistant materials such as fiberglass, silica, or aramid, and is essential in environments like fabrication shops, shipyards, refineries, and power plants.

Welding blankets are typically categorized by material structure and performance class, falling into two main types:

Uncoated Fabric Blankets: Made from base materials (e.g., fiberglass or silica), these are suitable for general-purpose welding tasks.

- Light-duty models withstand up to 1,200°F (649°C), used in low-spark, clean environments.

- Medium-duty types handle up to 1,800°F (982°C), ideal for fabrication and routine welding.

- Heavy-duty variants resist up to 2,000°F (1,093°C), used in shipbuilding and foundries.

Coated Welding Blankets: Enhanced with silicone, acrylic, neoprene, or vermiculite coatings, these blankets resist abrasion, moisture, and brief exposure up to 2,300°F (1,260°C).

- Specialty coatings (e.g., aluminized or ceramic) can handle radiant heat over 3,000°F (1,649°C) in extreme settings like plasma cutting or aerospace fabrication.

Selection depends on temperature rating, exposure duration (continuous vs. intermittent), and compliance needs—many high-risk sites require blankets that meet ANSI Z49.1 or FM Approved standards.

Is a Welding Blanket Truly Fireproof?

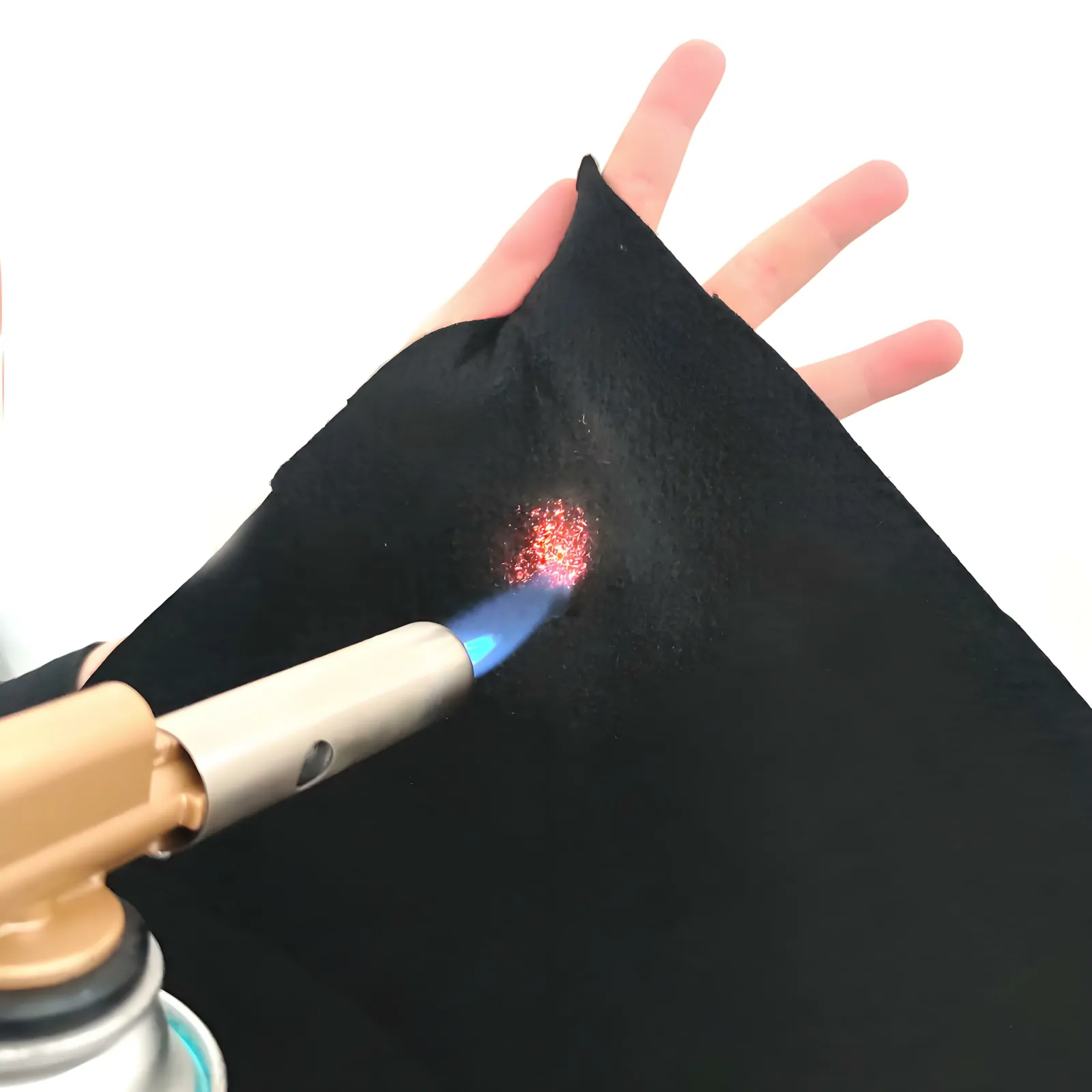

The term “fireproof” can be misleading in industrial safety. A retardant welding blanket is not entirely non-combustible but is engineered to be flame retardant, providing protection against high temperature, sparks, and molten metal.

Approximately 85% of blankets for welding in the U.S. market are made from fiberglass, silica, or ceramic fiber fabrics, each offering different heat resistance levels:

Fiberglass: up to 1200°F (649°C)

Silica: up to 1800°F (982°C)

Ceramic: up to 2300°F (1260°C)

Heavy duty coated blankets—using silicone, vermiculite, or acrylic—offer improved resistance to moisture, oil, and chemicals, making them ideal for shipyards, offshore platforms, and chemical facilities. In such conditions, coated fire blankets can last 5–7 years, compared to 2–3 years for uncoated alternatives. Shelf life may also double when stored properly.

For safety compliance, choose flame retardant welding blankets certified by FM Approvals, or meeting OSHA 1910.252 and NFPA 51B. These certifications ensure true fire protection—not just marketing claims.

Welding Blanket vs Fire Blanket

What is the difference between a welding blanket and a fire blanket?

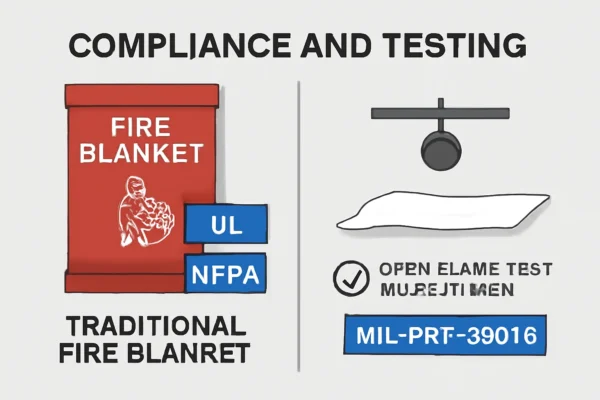

Although they may look similar, a high-temperature welding blanket and a fire blanket are made for entirely different applications—and using the wrong one can lead to serious safety risks, equipment damage, or regulatory violations.

A high-temperature welding blanket is a type of safety equipment built from high-temperature materials such as fiberglass, silica, or aramid fibers. Many models feature coatings like silicone, vermiculite, or acrylic to enhance resistance against moisture, slag, and chemical exposure. These blankets are engineered to withstand continuous exposure to temperatures as high as 2,300°F (1,260°C) and are widely used in shipyards, fabrication shops, and power plants to shield structures and personnel from molten metal, sparks, and radiant heat.

A fire blanket, by contrast, is a lightweight, single-use item designed to smother small fires by cutting off the oxygen supply. While it belongs to the same general category as fire extinguishers, a fire blanket is typically made of treated fiberglass or wool and is most often found in homes, kitchens, and emergency kits. However, it is not suitable for hot work tasks such as welding or grinding, due to its limited durability under high temperature exposure.

Importantly, a high-temperature welding blanket can sometimes substitute for a fire blanket in emergencies, but not the other way around. Fire blankets cannot withstand the molten metal splatter or sustained thermal exposure found in welding environments. Additionally, welding blankets are manufactured with features such as metal grommets, heat-resistant thread, and reinforced edges—components rarely found in fire blankets. This construction complexity also contributes to higher cost: welding blankets can cost three to four times more than standard fire blankets. Using one for basic fire suppression is usually overkill for the job—like bringing a tank to a knife fight.

Another important difference involves direct contact with skin. Fire blankets are sometimes wrapped around individuals during emergencies, especially in cases of clothing fires. Therefore, they are designed using low-irritation, non-toxic materials. Welding blankets, however, are not intended for human contact and may include coatings or fibers unsuitable for skin.

From a regulatory standpoint, welding blankets must comply with industrial hot work standards such as OSHA 1910.252, NFPA 51B, or ANSI/FM 4950. Fire blankets, on the other hand, are governed by consumer safety standards like ASTM F1989 or EN 1869. Using a non-rated fire blanket in place of proper welding safety equipment could result in code violations or voided insurance claims.

| Feature | Welding Blanket | Fire Blanket |

| Primary Purpose | Hot work protection (welding, cutting, grinding) | Emergency fire suppression |

| Material Composition | Fiberglass, silica, aramid (often coated) | Fiberglass or treated wool |

| Temperature Resistance | 1,000°F – 2,300°F (538°C – 1,260°C) | 500°F – 1,000°F (260°C – 538°C) |

| Use Environment | Industrial, construction, marine, energy sectors | Residential, kitchens, commercial fire safety |

| Regulatory Standards | OSHA 1910.252, NFPA 51B, FM Approvals | ASTM F1989, EN 1869 |

| Reusability | Reusable, long-term use | Typically single-use or limited-use |

| Moisture/Chemical Resistance | Yes (coated models) | No |

| Cost | Medium to High | Low |

| Skin Contact Safety | Not designed for skin contact; may irritate | Designed for safe human contact; low skin irritation |

Applications & Limitations

What is the purpose of a welding blanket?

Welding blankets aren’t just accessories—they’re frontline safety equipment in hot work environments. Across industries like automotive fabrication, shipbuilding, steel construction, and power generation, welding blankets are relied on daily to safeguard personnel, shield equipment, and protect surrounding areas from sparks, spatter, and molten metal.

For plant managers and welders alike, the benefits are clear: reduced downtime, better regulatory compliance, lower fire risk, and extended equipment lifespan. Coated welding blankets, in particular, deliver excellent performance under heat, abrasion, and chemical exposure—making them one of the most practical and cost-effective fire protection solutions available.

That said, no fire blanket is without limits—and welding blankets are no exception.

In high-risk, gas-rich environments like offshore platforms, petrochemical plants, and confined spaces with poor ventilation, blankets designed to protect against surface-level heat are not enough. According to the U.S. Chemical Safety Board (CSB), more than 40% of hot work-related explosions occur in areas without proper atmospheric controls. In these scenarios, hot work must be performed inside a Welding Habitat System—a sealed, gas-monitored, flame retardant enclosure built for hazardous work. Only when combined with FM Approvals-certified welding blankets can operations meet compliance and safety standards in these environments.

Another common misconception involves coated welding blankets and EV fire blankets. While both use layered flame retardant and heat resistant materials, their performance profiles and safety applications differ entirely. EV blankets are built to withstand thermal runaway from lithium-ion batteries, requiring much higher mass per area, increased thickness, and prolonged heat containment. Substituting one for the other risks catastrophic failure in either application. The message is clear: know the specs, know the hazard, and use the right blanket.

Welding blankets are indispensable—but they are not standalone solutions. In modern industrial safety, they function best as part of an integrated risk mitigation system, not a one-size-fits-all fix.

Use With Caution

Welding blankets, while effective against sparks and molten metal, are not gas-sealed or explosion-proof. In volatile atmospheres, always pair them with a certified Welding Habitat System and continuous gas monitoring, as required by OSHA 1910.146 and API RP 2009.

Choosing the Right Welding Blanket

Choose the right welding blanket depends largely on the type of welding process, the intensity of heat and spatter, and the worksite conditions.

- MIG (GMAW) & Arc Welding: These processes produce high levels of spatter and radiant heat. Use coated, heavy-duty blankets (e.g., silicone- or vermiculite-coated fiberglass) rated for at least 1,800°F (982°C).

- TIG (GTAW): Produces minimal spatter, so lightweight base fabric blankets are often sufficient—especially in clean indoor environments.

- Oxy-fuel & Plasma Cutting: Generates extreme heat and molten slag; requires high-temperature blankets rated above 2,000°F (1,093°C) and with good slag resistance.

- If you’re working in confined spaces, oil & gas, or chemical zones, always use coated models with chemical resistance, and ensure they carry FM Approvals, or comply with OSHA 1910.252 and NFPA 51B.

For mission-critical jobs, look for specifications like:

- Temperature rating (continuous vs. peak)

- Coating type (silicone, neoprene, vermiculite)

- Weave density / GSM

- Certifications (FM, EN, ASTM)

Whether you’re working in automotive fabrication, structural steel, or oil & gas, your safety gear should match your risk level—and that starts with the right blanket.

At Safeprotex, we don’t just manufacture blankets—we engineer fire protection solutions. With over 20 years of experience in welding blanket development, our team understands the complexities of real-world applications.

Talk to one of our experts today and get a custom recommendation based on your welding process, environment, and compliance needs.

We’ll help you find the right welding protection—not just a product, but a solution.