Home » Welding Blanket » Welding Screen

Welding Screen

Safeprotex manufactures FM4950-certified welding screens engineered to create safe, flexible welding zones for industrial and workshop use. These screens block sparks, spatter, and debris to prevent fire hazards and improve operator safety.

Built from PVC or advanced fabrics such as silicone-coated fiberglass, PTFE-coated fiberglass, and high-silica cloth, welding curtains cover heat exposure from 250°C to 1650°C (482–3002°F). Each fabric is engineered for low smoke, tear resistance, and optical safety.

All Safeprotex welding screens comply with FM4950 and meet UL94 VTM-0 flammability standards, ensuring proven performance for light-duty, medium, and factory-grade welding protection setups.

Material:

PVC

Silicone

PTFE

High Silica

Customization

Safeprotex manufactures a comprehensive range of FM4950-certified welding screens designed to create safe, modular welding zones for industrial and personal use. These screens effectively block sparks, spatter, and hot debris, reducing the risk of fire and injury in welding environments. Built for both fixed and mobile setups, Safeprotex welding screens deliver reliable protection while maintaining workspace flexibility and visibility.In addition to standard PVC welding screens, Safeprotex offers a full spectrum of high-performance technical fabrics, engineered to withstand diverse welding processes including fusion welding, solid-state welding, and brazing.

Available materials include:

Silicone-coated fiberglass fabric – temperature resistance up to 250–550°C (480–1020°F)

PTFE-coated fiberglass fabric – outstanding chemical and thermal stability up to 600°C (1110°F)

High-silica fabric – continuous protection up to 1000°C (1830°F)

Coated high-silica fabric – extreme protection up to 1650°C (3000°F)

These options allow Safeprotex to tailor each solution to meet small-scale workshop, medium industrial, or factory-grade welding protection needs.Safeprotex welding screens are FM Approved to FM4950, ensuring proven flame resistance and performance reliability under industrial fire-safety standards.

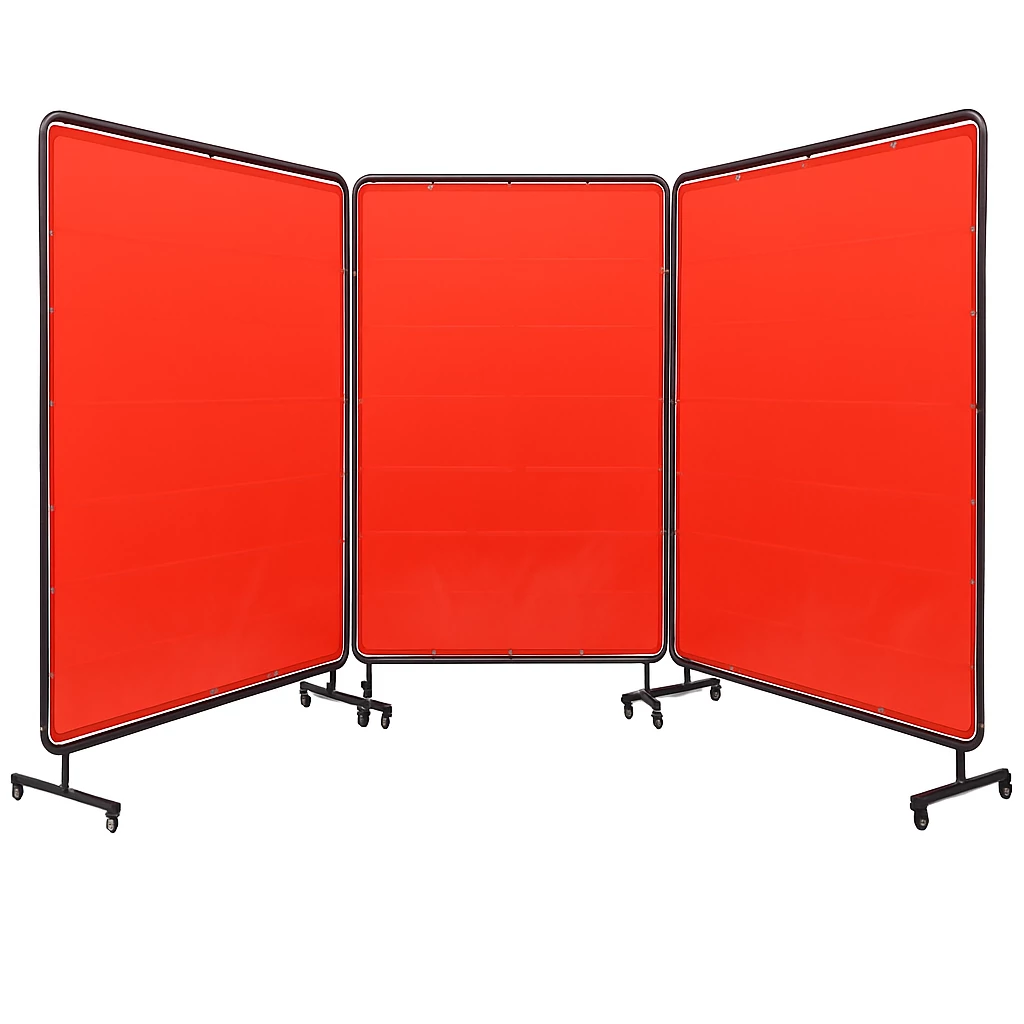

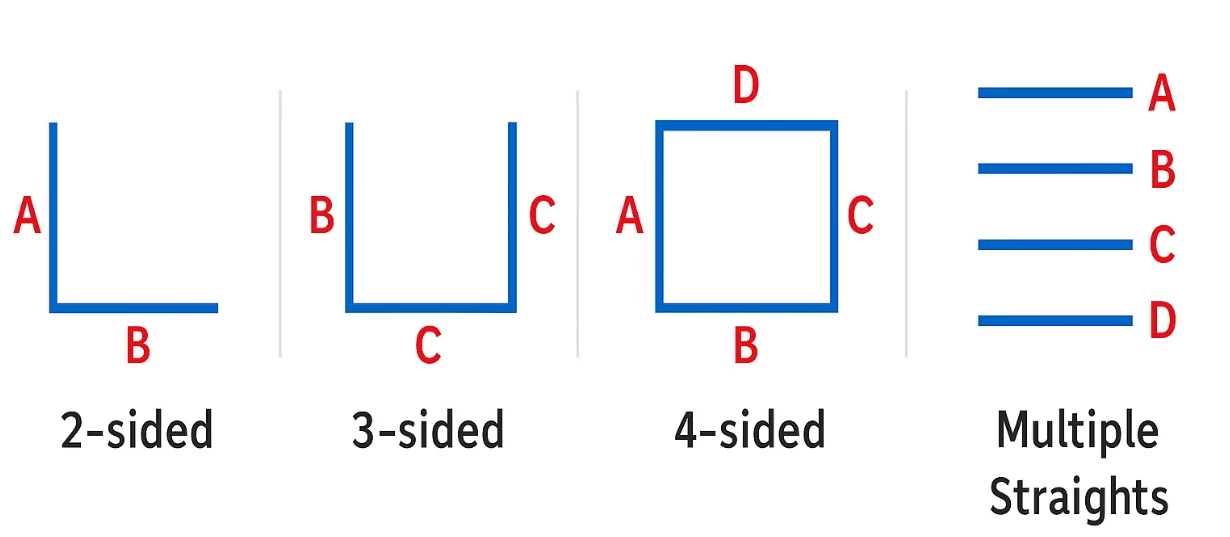

Safeprotex welding screens can be configured as straight, 2-sided, 3-sided, or 4-sided enclosures to match different workspace needs. The straight type separates stations; the 2- and 3-sided layouts form corner or U-shaped barriers; the 4-sided setup creates a fully enclosed booth. Multiple straight panels can also be aligned for modular, expandable protection.

| Parameter | Specification | Notes / Compliance |

| Certification | FM Approved (FM4950) | Meets UL94 VTM-0 flammability test |

| Operating Temperature Range | 250°C – 1650°C (482°F – 3002°F) | Varies by material type |

| Available Materials | PVC, Silicone-coated Fiberglass, PTFE-coated Fiberglass, High-Silica Fabric | Custom coating and color options available |

| Typical Fabric Weight | 450 – 1100 g/m² | Balances flexibility and durability |

| Visible-Light Transmittance | 1 – 15 % (PVC variants) | Reduces arc glare, maintains visibility |

| Tear / Tensile Strength | > 100 N (avg.) | Supports extended service life |

| Smoke Emission | Low (per FM 4950 criteria) | Suitable for indoor welding zones |

| Compliance | OSHA 1910 Subpart Q / NFPA 51B | Hot-work safety standard alignment |

| Configurations | Straight, L-Shape, U-Shape, Enclosed Booth | Modular, interconnectable system design |

Safeprotex welding screens are used in metal fabrication plants, automotive workshops, shipyards, and industrial maintenance facilities to define safe welding zones and contain sparks, spatter, and UV radiation. They help facilities comply with OSHA 1910 Subpart Q and NFPA 51B hot-work standards while maintaining visibility and workflow efficiency. Suitable for both fixed and mobile setups, these screens provide reliable fire-safety separation in any hot-work environment.

- FM4950

- UL94 V0

COMPREHENSIVE SOLUTIONS TAILORED FOR YOUR NEEDS

Safeprotex provides custom fire safety solutions to meet the unique needs of your business. Whether you’re looking for design services, product customization, R&D, wholesale supply, or specialized solutions for your industry, simply fill out the form on the right to get started.

- Free Technical Support: Always available to assist you with product and application guidance.

- Custom Design Solutions: Tailored fire safety solutions specific to your needs.

- Industry-Specific Expertise: Extensive solutions across various sectors, from manufacturing to automotive to high-risk environments.

- Competitive Pricing: High-quality fire protection without compromising your budget.

- Lifetime Service Support: Dedicated advisors to ensure your ongoing safety and satisfaction.

And that’s just the beginning!

GET IN TOUCH

Fill out the quick form below, and our sales team will contact you in a flash!