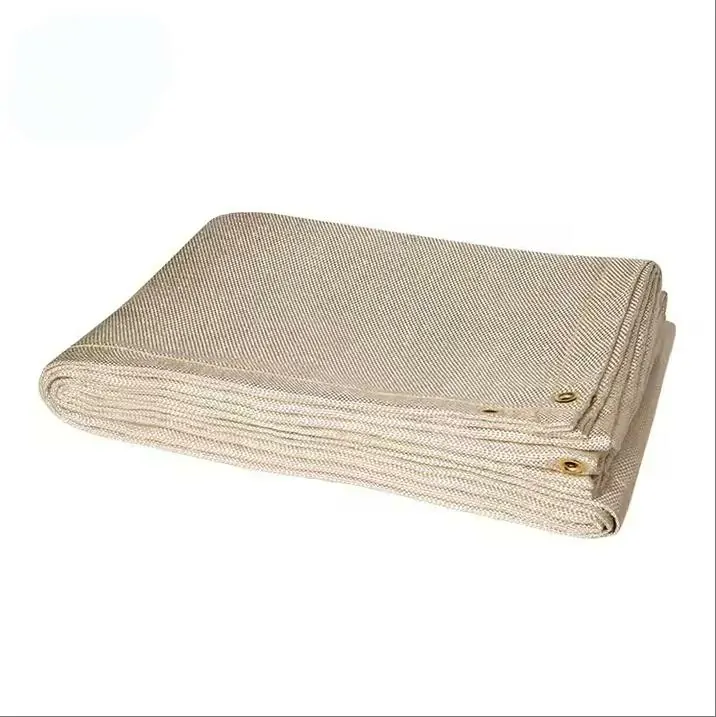

A fire blanket is a crucial fire safety tool designed to extinguish small fires by smothering the flames and cutting off the oxygen supply, which is one of the key elements necessary for combustion. By suffocating the fire, the fire blanket halts its spread and prevents further damage. Fire blankets work by creating a barrier that deprives the fire of oxygen, stopping it from continuing to burn. Fire blankets are typically made from fire-resistant materials such as fiberglass, high-silica fabric, or materials coated with silicone, vermiculite, or graphite. These blankets are compact, lightweight, and easy to deploy, making them ideal for both residential and industrial environments.

Fire blankets are commonly used in kitchens, laboratories, workshops, and industrial settings, where they can quickly suppress a small fire before it escalates. For example, pan fire situations in kitchens can be managed effectively with a fire blanket, preventing serious accidents. Unlike fire extinguishers, which may require specific training and may not be suitable for certain types of fires, fire blankets are simple to use and can be deployed quickly in emergency situations, making them a crucial part of fire safety protocols. They are also especially useful when clothes are on fire, as the blanket can be used to wrap around the person and put out the flames.

In addition, fire blankets are also effective when a person whose clothes are on fire needs immediate assistance, allowing someone nearby to smother the flames and prevent further injury. These blankets are an essential part of fire safety equipment for homes and businesses, especially in environments where fires may start quickly, such as kitchens or workshops. When a person or object catches fire, having a fire blanket nearby can help mitigate damage and save lives.

What is a Fire Blanket Made Of?

Fire blankets are tightly woven fabric used to smother and extinguish a fire, each designed to handle specific fire hazards. Below are the different types of fire blankets and their properties:

Base Fabric Fire Blankets:

These blankets are made from tightly woven fibers without additional coatings, providing effective fire resistant fabrics for general use.

Fiberglass Fire Blankets

Made from woven fiberglass fibers, these blankets are the most common and versatile type. They are perfect for general fire safety, especially in environments with moderate heat, such as kitchens. Fiberglass blankets can withstand high temperatures up to 550°C (1,022°F), making them ideal for grease fires and small fires. Their flexibility allows them to cover irregular surfaces like pots or cooking equipment, effectively smothering the flames. These blankets are excellent for putting out small fires before they escalate.

High-Silica Fire Blankets

Woven from high-silica fibers, these blankets are designed to withstand extreme high temperatures, typically up to 1,000°C (1,832°F). High-silica blankets are best suited for high-heat industrial environments, such as welding stations, foundries, and other settings involving molten metals or intense heat. They are perfect for industries where high-temperature operations create serious fire hazards.

Wool Fire Blankets

Made from natural wool fibers, these blankets are naturally flame resistant and are typically used in situations with lower heat hazards. While not suitable for extreme conditions, wool fire blankets provide a lightweight and flexible option for fire safety in laboratory environments or areas with minimal fire hazard. They are designed for use in less hazardous settings, providing protection in low-heat fires.

Aramid Fiber Fire Blankets

Constructed from synthetic aramid fibers like Kevlar or Nomex, these blankets combine heat resistance with mechanical strength. Aramid fiber blankets are perfect for environments where fire hazards are combined with impact, abrasion, or high-velocity concerns, such as in the automotive or aerospace industries. Known for their strength and durability, these blankets can withstand harsh conditions and are used for protecting machinery and personnel in high-risk areas.

Coated Fire Blankets

Coated fire blankets provide additional protection by using specialized coatings to enhance their resistance to chemicals, liquid flames, or molten materials. These blankets are used in more specific industrial applications where such hazards are present.

Silicone-Coated Fire Blankets

These fire blankets have a fiberglass base with a silicone coating that enhances their resistance to chemical reactions and high-temperature liquid flames. They can withstand temperatures up to 550°C (1,022°F) and are commonly used in commercial kitchens, laboratories, and other environments where grease or chemical fires may occur. The silicone coating also provides resistance to chemical corrosion, making these blankets highly durable in such environments. These are ideal for situations where the oxygen supply needs to be quickly cut off to stop the fire.

Vermiculite-Coated Fire Blankets

Vermiculite is a heat-resistant mineral that is applied to fiberglass blankets, providing extra protection against molten metals and extreme heat. These blankets are particularly useful in high-temperature industrial environments such as welding, metalworking, and cutting operations. Vermiculite-coated fire blankets can endure temperatures as high as 1,200°C (2,192°F), making them suitable for extreme conditions. They provide additional fire retardant properties to protect against the spread of fire.

Graphite-Coated Fire Blankets

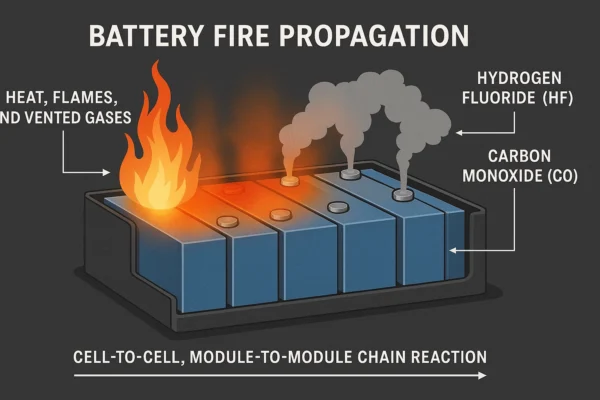

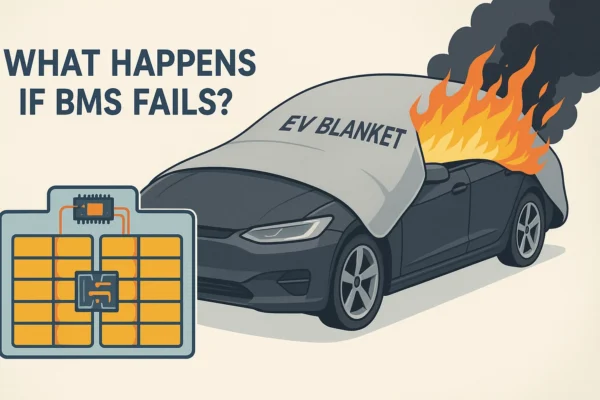

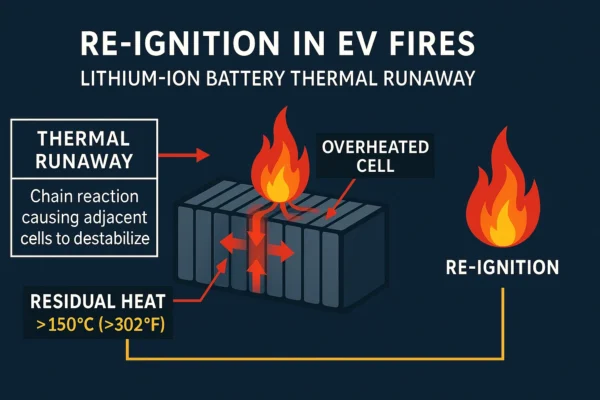

These blankets feature a high-silica base coated with graphite, offering superior heat dissipation and preventing re-ignition. Graphite-coated blankets are ideal for extreme fire situations, such as those involving lithium-ion batteries or fires in aviation environments. These blankets are capable of handling temperatures up to 1,100°C (2,012°F) and are specifically designed to prevent the risk of re-ignition by quickly dispersing heat. This makes them an excellent option for flame resistant environments.

What is the Purpose of a Fire Blanket?

The core purpose of fire blankets is to extinguish small fires by cutting off the oxygen supply—without using chemicals, water, or complex equipment. This makes them an essential tool for both home and industrial fire safety, especially in situations where a fire extinguisher may not be practical or safe to deploy.

Unlike extinguishers that release pressurized agents, fire blankets are non-reactive, made of fire resistant materials, and easy to use—ideal for enclosed areas or sensitive environments. They are particularly effective against Class A (combustibles), Class B (flammable liquids), and Class K (cooking oils and fats) fires.

For example, in a grease fire, a fire blanket allows you to smother flames without spreading hot oil—unlike water, which can make such fire hazards worse. In clothing fires, it provides a safe way to wrap the victim and prevent the fire from spreading, often before emergency responders arrive.

In industrial and high-heat settings, fire blankets made from fire resistant materials such as high-silica fabric or graphite coatings are designed to extinguish intense heat events and protect against molten metal or battery flare-ups. They’re trusted in welding, manufacturing, and EV battery storage, where containment is critical.

Though not suitable for fast-spreading fires or energized electrical equipment, fire blankets serve as a vital first-response fire emergency tool. When stored in a wall mounted case or pouch, they remain quickly accessible and easy to deploy. Certified under EN 1869 and other safety standards, fire blankets are widely used in fire safety protocols for commercial kitchens, laboratories, vehicles, and even aviation.

How Do Fire Blankets Work?

Fire blankets work by cutting off the oxygen supply to the fire, effectively suffocating it. The materials used in the blanket determine its effectiveness for specific fire types. Fire blankets are designed to tightly conform to the fire source, blocking oxygen and absorbing heat:

Fiberglass Blankets: These blankets are highly flexible and tightly adhere to the fire, forming a barrier that isolates the flames from the surrounding oxygen. They are ideal for small kitchen fires and general use.

Silicone-Coated Blankets: In addition to cutting off oxygen, these blankets also resist high-temperature liquid flames and chemical reactions, making them ideal for grease and chemical fires in kitchens or laboratories. They are stable in temperatures from 260°C to 550°C (500°F–1,022°F).

Vermiculite-Coated Blankets: The vermiculite coating provides extra protection against molten metals and sparks, making them suitable for industrial applications. These blankets can endure temperatures up to 1,200°C (2,192°F).

Graphite-Coated Blankets: Designed for extreme environments, these blankets dissipate heat while preventing re-ignition. They are ideal for situations involving lithium-ion batteries or high-heat environments like aviation, and can withstand temperatures up to 1,100°C (2,012°F).

Make Sure Your Fire Blanket Works

To ensure that your fire blanket will work effectively when needed, it’s important to:

Check Certifications: Make sure the blanket meets industry certifications like UL94 (Standard for Flammability of Plastic Materials),DIN SPEC 91489:2024-11 or UL723 (Surface Burning Characteristics), and verify that it complies with the EV blankets standard for optimal performance.

Regular Inspections: Periodically check your fire blanket for wear and tear, particularly if your fire blankets has been used before or exposed to harsh environments. Replace any damaged blankets immediately.

Proper Storage: Store your fire blanket in an easily accessible location, such as near the kitchen stove or industrial workstations, where it can be quickly deployed during an emergency.

How to Use a Fire Blanket

Pull the Tabs: Remove the fire blanket from its storage case by pulling the tabs located on the sides of the case.

Protect Yourself: Hold the blanket by the edges to avoid direct contact with the flames.

Cover the Fire: Gently place the blanket over the fire, ensuring it completely covers the flames. Hold it in place for several minutes until the fire is fully extinguished.

After Use: Never remove the blanket immediately after use; let it stay in place to ensure the fire has been fully suppressed. If the blanket is damaged or soiled, replace it immediately.

Special Considerations for Different Fires:

- Kitchen Fires: When dealing with grease fires, cover the pan or fire source without moving it to prevent spreading the flames.

- Electrical Fires: Ensure the fire blanket is non-conductive and suitable for electrical fires before use.

At Safeprotex, a leading fire blanket suppliers, we offer one of the most comprehensive selections on the market. Yet, it’s our industry-leading expertise and dedicated service that truly set us apart. Connect with our experts or visit our store today to ensure you’re prepared before disaster strikes.